Refinery Maintenance: The Work Management Process

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenance efforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

Interested in topics related to “Refinery Maintenance”? Click the buttons below to check out our related industry insights.

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Refineries play a critical role in the processing of crude oil and the production of various petroleum products. Within these complex facilities, the storage and management of liquids, such as crude oil, intermediates, and finished products are of utmost importance. To ensure efficient operations, accurate inventory management, and safe working conditions, refineries rely heavily on tank gauging systems. The following will explore the significance of tank gauging in refineries and how it contributes to the overall success of these facilities.

Different Tank Gauging Methods

While different gauging techniques are used depending on the type of tank and the unique properties of the liquid being stored, tank gauging methods can be divided into two general categories – manual and automatic. An automatic tank gauge (ATG) is an electronic device whose purpose is to continuously monitor levels. ATGs also provide refinery operators with details regarding what is happening inside the tank (e.g., changes in level, level warnings, water level and volume, and temperature). Alternatively, a manual gauge can be carried out using one of 2 techniques: innage (tells you the actual depth of the liquid inside the tank) or outage (measures the part of the tank that is not filled with liquid).

While it can be tempting to solely rely on ATGs for information, recall that all equipment must be calibrated to ensure accuracy. Considering the size of storage tanks, a difference of a quarter inch in level measurement could equal thousands of barrels. Now that we have a better understanding of different methods for tank gauging, let’s explore some of the benefits of using a combined approach for ATG and manual tank gauging at the refinery.

Accurate Inventory Management

Tank gauging provides accurate measurement of liquid levels and volumes in storage tanks. Precise knowledge of inventory levels is essential for production planning and scheduling. Accurate inventory data helps optimize storage capacity and minimize product losses. Compliance with Safety Regulations Refineries operate under strict safety regulations and guidelines. Tank gauging ensures compliance with regulations regarding storage tank safety. Accurate level monitoring helps prevent overfilling and the associated risks. Moreover, by eliminating inventory inaccuracy as a potential source for error, the refinery is better able to reconcile mass balance and more efficiently identify sources of loss (e.g., meter equipment issues, density measurements, etc.).

Leak Detection and Environmental Protection

Tank gauging systems play a crucial role in early leak detection. Continuous monitoring of tank levels helps identify potential leaks promptly. Detecting leaks promptly minimizes environmental impact and prevents product loss.

Operational Efficiency

Tank gauging systems enable real-time monitoring of tank levels and product movement. Operators can track inventory levels, identify bottlenecks, and optimize processes. Accurate data helps streamline operations, reduce downtime, and increase efficiency.

Maintenance and Asset Management

Tank gauging systems aid in predictive maintenance and asset management. Continuous monitoring of tank conditions helps identify maintenance needs. Early detection of equipment malfunctions reduces the risk of costly breakdowns.

Integration with Control Systems

Tank gauging systems can be integrated with refinery control systems. Integration allows for seamless monitoring and control of tank levels and operations. Real-time data integration facilitates decision-making and enhances overall refinery control.

Emergency Response and Contingency Planning

In the event of emergencies, such as fires or leaks, tank gauging data is invaluable. Accurate and up-to-date information aids emergency response teams. Tank gauging systems assist in developing effective contingency plans.

Calibration and Accuracy Verification

Regular calibration and verification of tank gauging systems are essential. Calibration ensures accurate measurement and reliable data. Regular verification confirms that the system remains within acceptable accuracy limits.

Operator Safety and Ease of Operation

Tank gauging systems enhance operator safety and ease of operation. Accurate level measurements reduce the need for manual gauging, minimizing exposure to hazards. Automated systems provide operators with real-time information, enhancing situational awareness.

Continuous Improvement and Optimization

In conclusion, refineries are constantly striving for improvement and optimization. Tank gauging data plays a vital role in identifying opportunities for optimization. Analyzing historical data helps refine processes, reduce waste, and enhance overall performance. Tank gauging is an indispensable component of refinery operations. It ensures accurate inventory management, compliance with safety regulations, early leak detection, operational efficiency, and much more. By investing in reliable tank gauging systems and embracing continuous improvement, refineries can achieve optimal performance, maintain safety standards, and contribute to the sustainable growth of the industry.

This article was written by Francesca D’Urso, an Engagement Manager at Trindent Consulting.

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality: During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture: Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

Refinery Maintenance: Planning for Success

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality: During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture: Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

Interested in topics related to “Refinery Maintenance”? Click the buttons below to check out our related industry insights.

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Refineries play a critical role in the processing of crude oil and the production of various petroleum products. Within these complex facilities, the storage and management of liquids, such as crude oil, intermediates, and finished products are of utmost importance. To ensure efficient operations, accurate inventory management, and safe working conditions, refineries rely heavily on tank gauging systems. The following will explore the significance of tank gauging in refineries and how it contributes to the overall success of these facilities.

Different Tank Gauging Methods

While different gauging techniques are used depending on the type of tank and the unique properties of the liquid being stored, tank gauging methods can be divided into two general categories – manual and automatic. An automatic tank gauge (ATG) is an electronic device whose purpose is to continuously monitor levels. ATGs also provide refinery operators with details regarding what is happening inside the tank (e.g., changes in level, level warnings, water level and volume, and temperature). Alternatively, a manual gauge can be carried out using one of 2 techniques: innage (tells you the actual depth of the liquid inside the tank) or outage (measures the part of the tank that is not filled with liquid).

While it can be tempting to solely rely on ATGs for information, recall that all equipment must be calibrated to ensure accuracy. Considering the size of storage tanks, a difference of a quarter inch in level measurement could equal thousands of barrels. Now that we have a better understanding of different methods for tank gauging, let’s explore some of the benefits of using a combined approach for ATG and manual tank gauging at the refinery.

Accurate Inventory Management

Tank gauging provides accurate measurement of liquid levels and volumes in storage tanks. Precise knowledge of inventory levels is essential for production planning and scheduling. Accurate inventory data helps optimize storage capacity and minimize product losses. Compliance with Safety Regulations Refineries operate under strict safety regulations and guidelines. Tank gauging ensures compliance with regulations regarding storage tank safety. Accurate level monitoring helps prevent overfilling and the associated risks. Moreover, by eliminating inventory inaccuracy as a potential source for error, the refinery is better able to reconcile mass balance and more efficiently identify sources of loss (e.g., meter equipment issues, density measurements, etc.).

Leak Detection and Environmental Protection

Tank gauging systems play a crucial role in early leak detection. Continuous monitoring of tank levels helps identify potential leaks promptly. Detecting leaks promptly minimizes environmental impact and prevents product loss.

Operational Efficiency

Tank gauging systems enable real-time monitoring of tank levels and product movement. Operators can track inventory levels, identify bottlenecks, and optimize processes. Accurate data helps streamline operations, reduce downtime, and increase efficiency.

Maintenance and Asset Management

Tank gauging systems aid in predictive maintenance and asset management. Continuous monitoring of tank conditions helps identify maintenance needs. Early detection of equipment malfunctions reduces the risk of costly breakdowns.

Integration with Control Systems

Tank gauging systems can be integrated with refinery control systems. Integration allows for seamless monitoring and control of tank levels and operations. Real-time data integration facilitates decision-making and enhances overall refinery control.

Emergency Response and Contingency Planning

In the event of emergencies, such as fires or leaks, tank gauging data is invaluable. Accurate and up-to-date information aids emergency response teams. Tank gauging systems assist in developing effective contingency plans.

Calibration and Accuracy Verification

Regular calibration and verification of tank gauging systems are essential. Calibration ensures accurate measurement and reliable data. Regular verification confirms that the system remains within acceptable accuracy limits.

Operator Safety and Ease of Operation

Tank gauging systems enhance operator safety and ease of operation. Accurate level measurements reduce the need for manual gauging, minimizing exposure to hazards. Automated systems provide operators with real-time information, enhancing situational awareness.

Continuous Improvement and Optimization

In conclusion, refineries are constantly striving for improvement and optimization. Tank gauging data plays a vital role in identifying opportunities for optimization. Analyzing historical data helps refine processes, reduce waste, and enhance overall performance. Tank gauging is an indispensable component of refinery operations. It ensures accurate inventory management, compliance with safety regulations, early leak detection, operational efficiency, and much more. By investing in reliable tank gauging systems and embracing continuous improvement, refineries can achieve optimal performance, maintain safety standards, and contribute to the sustainable growth of the industry.

This article was written by Francesca D’Urso, an Engagement Manager at Trindent Consulting.

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenance efforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Refineries play a critical role in the processing of crude oil and the production of various petroleum products. Within these complex facilities, the storage and management of liquids, such as crude oil, intermediates, and finished products are of utmost importance. To ensure efficient operations, accurate inventory management, and safe working conditions, refineries rely heavily on tank gauging systems. The following will explore the significance of tank gauging in refineries and how it contributes to the overall success of these facilities.

Different Tank Gauging Methods

While different gauging techniques are used depending on the type of tank and the unique properties of the liquid being stored, tank gauging methods can be divided into two general categories – manual and automatic. An automatic tank gauge (ATG) is an electronic device whose purpose is to continuously monitor levels. ATGs also provide refinery operators with details regarding what is happening inside the tank (e.g., changes in level, level warnings, water level and volume, and temperature). Alternatively, a manual gauge can be carried out using one of 2 techniques: innage (tells you the actual depth of the liquid inside the tank) or outage (measures the part of the tank that is not filled with liquid).

While it can be tempting to solely rely on ATGs for information, recall that all equipment must be calibrated to ensure accuracy. Considering the size of storage tanks, a difference of a quarter inch in level measurement could equal thousands of barrels. Now that we have a better understanding of different methods for tank gauging, let’s explore some of the benefits of using a combined approach for ATG and manual tank gauging at the refinery.

Accurate Inventory Management

Tank gauging provides accurate measurement of liquid levels and volumes in storage tanks. Precise knowledge of inventory levels is essential for production planning and scheduling. Accurate inventory data helps optimize storage capacity and minimize product losses. Compliance with Safety Regulations Refineries operate under strict safety regulations and guidelines. Tank gauging ensures compliance with regulations regarding storage tank safety. Accurate level monitoring helps prevent overfilling and the associated risks. Moreover, by eliminating inventory inaccuracy as a potential source for error, the refinery is better able to reconcile mass balance and more efficiently identify sources of loss (e.g., meter equipment issues, density measurements, etc.).

Leak Detection and Environmental Protection

Tank gauging systems play a crucial role in early leak detection. Continuous monitoring of tank levels helps identify potential leaks promptly. Detecting leaks promptly minimizes environmental impact and prevents product loss.

Operational Efficiency

Tank gauging systems enable real-time monitoring of tank levels and product movement. Operators can track inventory levels, identify bottlenecks, and optimize processes. Accurate data helps streamline operations, reduce downtime, and increase efficiency.

Maintenance and Asset Management

Tank gauging systems aid in predictive maintenance and asset management. Continuous monitoring of tank conditions helps identify maintenance needs. Early detection of equipment malfunctions reduces the risk of costly breakdowns.

Integration with Control Systems

Tank gauging systems can be integrated with refinery control systems. Integration allows for seamless monitoring and control of tank levels and operations. Real-time data integration facilitates decision-making and enhances overall refinery control.

Emergency Response and Contingency Planning

In the event of emergencies, such as fires or leaks, tank gauging data is invaluable. Accurate and up-to-date information aids emergency response teams. Tank gauging systems assist in developing effective contingency plans.

Calibration and Accuracy Verification

Regular calibration and verification of tank gauging systems are essential. Calibration ensures accurate measurement and reliable data. Regular verification confirms that the system remains within acceptable accuracy limits.

Operator Safety and Ease of Operation

Tank gauging systems enhance operator safety and ease of operation. Accurate level measurements reduce the need for manual gauging, minimizing exposure to hazards. Automated systems provide operators with real-time information, enhancing situational awareness.

Continuous Improvement and Optimization

In conclusion, refineries are constantly striving for improvement and optimization. Tank gauging data plays a vital role in identifying opportunities for optimization. Analyzing historical data helps refine processes, reduce waste, and enhance overall performance. Tank gauging is an indispensable component of refinery operations. It ensures accurate inventory management, compliance with safety regulations, early leak detection, operational efficiency, and much more. By investing in reliable tank gauging systems and embracing continuous improvement, refineries can achieve optimal performance, maintain safety standards, and contribute to the sustainable growth of the industry.

This article was written by Francesca D’Urso, an Engagement Manager at Trindent Consulting.

Interested in topics related to “Refinery Maintenance”? Click the buttons below to check out our related industry insights.

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality: During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture: Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenance efforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

Maximizing Benefits through Advanced Process Control (APC) in Gasoline Blending

Advanced process control (APC) plays a crucial role in real-time analysis and recipe control for optimizing gasoline blending operations. However, to harness the full potential of these systems, users must be aware of key considerations. This article will explore three important caveats when implementing APC in gasoline blending: configuring the objective function, ensuring accurate parameters and constraints, and establishing a robust performance review process. By addressing these aspects, refineries can unlock the benefits of precise process control, automation, and financial advantages while adapting to lean operational environments.

Configuring the Objective Function:

To achieve optimal results, configuring the APC system’s objective function is essential. Refineries must customize the solution to align with their specific refinery posture and economic goals. Often, default settings from initial installation are utilized without considering individual circumstances. Refineries should assess and update these settings regularly to maximize performance and value delivery.

Parameters and Constraints:

The accuracy and timeliness of data feeding into the APC system are critical for effective gasoline blending. Refineries must ensure that data sources are up-to-date, reflecting daily operations and incorporating the latest lab data. Careful attention should be given to the calibration and accuracy of the data. Additionally, refining the constraints is vital to strike the right balance. Overly flexible constraints can lead to excessive fluctuations during adjustments, while overly tight constraints may hinder the system’s ability to provide optimized solutions.

Performance Review Process:

Regular performance reviews are essential to ensure that the APC system remains up-to-date and continuously improves. Refineries should establish a robust review process to assess the system’s configuration and identify additional optimization opportunities. By periodically evaluating system performance and exploring new features, refineries can enhance their operational efficiency, identify potential areas for improvement, and capitalize on emerging technologies.

Benefits of a Well-Configured APC System:

A well-configured APC system in gasoline blending brings numerous benefits. It enables precise process control, ensuring the production of optimal-quality gasoline within specifications. The high level of automation reduces manual intervention and empowers process control engineers and operators. In lean operational environments, a well-configured APC system can generate significant financial benefits, potentially amounting to tens of millions of dollars annually.

Conclusion:

Maximizing the benefits of APC in gasoline blending requires careful attention to key considerations. Configuring the objective function to align with refinery goals, ensuring accurate parameters and constraints, and implementing a robust performance review process are crucial steps. By addressing these caveats, refineries can achieve precise process control, automation, and substantial financial advantages in an increasingly lean operational landscape.

Interested in learning more about our services in the downstream sector? Check out our Energy page to explore our expertise and discover how we drive client success.

Interested in topics related to gasoline blending? Click the buttons below to check out our related industry insights.

How to Establish a Good Ethanol Uplift Model?

“How to establish a good ethanol uplift model?” has been a common question when it comes to gasoline blending. With the addition of 10% ethanol to a majority of gasoline products, accurate prediction of the final fuel properties is critical to mitigate margin erosion. With years of experience in blending optimization projects, at Trindent we have developed specific expertise in this area, and here are some insights:

Ethanol Uplift Model Best Practices

Each refinery has its configurations that are developed as a result of the molecules they are making. Therefore, picking the right independent variables to start the development of the model is critical. It starts with understanding the principle of what Octane Number (ON) is, and how this property is related to the chemical molecules inside the gasoline. Typically, a refinery can use as much as 7-8 independent variables, and around 10-15 iterations before finding the perfect model which is not only accurate but also intuitive. The complexity of the model is also important as you want to make it sophisticated enough to provide the accuracy you want, but also simple enough to integrate into the existing system with ease.

Managing Component Distribution

Once a model is developed – the next question would be – how do we optimize it? In addition to adjusting the ON of the neat blend stock (which is often the only approach most refineries take), refineries may take advantage of other property and compositional requirements between to maximize the overall benefit of ON uplift.

Going Beyond ON

While a lot of focus on the ethanol model is about ON, it is imperative to consider other properties that are also affected by ethanol. Therefore, a mature ethanol model system would consider other key properties such as RVP, distillation, and V/L. A good ethanol model system would allow a refinery to achieve method repeatability level giveaway for all their constrained parameters and maximize the benefit from production cost management.

How Does Butane Affect Gasoline Blending?

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity:

Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing:

After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How far in advance does the request need to be placed? Is it feasible to add additional volume? What is the quality of the product and how can it be monitored? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring:

This is one of the most critical factors to consider when managing butane – to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

How to Establish a Good Ethanol Uplift Model?

“How to Establish a Good Ethanol Uplift Model?”

“How to establish a good ethanol uplift model?” has been a common question when it comes to gasoline blending. With the addition of 10% ethanol to a majority of gasoline products, accurate prediction of the final fuel properties is critical to mitigate margin erosion. With years of experience in blending optimization projects, Trindent has developed specific expertise and these are our expert insights.

Ethanol Uplift Model Best Practices

Each refinery has its configurations that are developed as a result of the molecules they are making. Therefore, picking the right independent variables to start the development of the model is critical. It starts with understanding the principle of what Octane Number (ON) is, and how this property is related to the chemical molecules inside the gasoline. Typically, a refinery can use as much as 7-8 independent variables, and around 10-15 iterations before finding the perfect model which is not only accurate but also intuitive. The complexity of the model is also important as you want to make it sophisticated enough to provide the accuracy you want, but also simple enough to integrate into the existing system with ease.

Managing Component Distribution

Once a model is developed – the next question would be – how do we optimize it? In addition to adjusting the ON of the neat blend stock (which is often the only approach most refineries take), refineries may take advantage of other property and compositional requirements between to maximize the overall benefit of ON uplift.

Going Beyond ON

While a lot of focus on the ethanol model is about ON, it is imperative to consider other properties that are also affected by ethanol. Therefore, a mature ethanol model system would consider other key properties such as RVP, distillation, and V/L. A good ethanol model system would allow a refinery to achieve method repeatability level giveaway for all their constrained parameters and maximize the benefit from production cost management.

This article was written by KAI Y. WAN, an Associate Principal at Trindent Consulting. Dr. Wan has collaborated closely with multiple business partners in the energy sector across North America and Asia-Pacific, including some of the world’s largest refineries, and has delivered > $300 MM in financial improvements, with typical project ROIs at 500%–1,500% during the first year after implementation.

Interested in learning more about our services in the downstream sector? Check out our Energy page to explore our expertise and discover how we drive client success.

Interested in topics related to gasoline blending? Click the buttons below to check out our related industry insights.

How Does Butane Affect Gasoline Blending?

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity: Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing: After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How soon in advance does the request need to be placed? How feasible is it to have an additional volume? How is the quality of the product and how to monitor it? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring: This is one of the most critical factors to consider when managing butane – to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

Maximizing Benefits through Advanced Process Control (APC) in Gasoline Blending

Introduction:

Advanced process control (APC) plays a crucial role in real-time analysis and recipe control for optimizing gasoline blending operations. However, to harness the full potential of these systems, users must be aware of key considerations. This article will explore three important caveats when implementing APC in gasoline blending: configuring the objective function, ensuring accurate parameters and constraints, and establishing a robust performance review process. By addressing these aspects, refineries can unlock the benefits of precise process control, automation, and financial advantages while adapting to lean operational environments.

Table of content:

Configuring the Objective Function

Parameters and Constraints

Performance Review Process

Benefits of a Well-Configured APC System

Conclusion

Configuring the Objective Function:

To achieve optimal results, configuring the APC system’s objective function is essential. Refineries must customize the solution to align with their specific refinery posture and economic goals. Often, default settings from initial installation are utilized without considering individual circumstances. Refineries should assess and update these settings regularly to maximize performance and value delivery.

Parameters and Constraints:

The accuracy and timeliness of data feeding into the APC system are critical for effective gasoline blending. Refineries must ensure that data sources are up-to-date, reflecting daily operations and incorporating the latest lab data. Careful attention should be given to the calibration and accuracy of the data. Additionally, refining the constraints is vital to strike the right balance. Overly flexible constraints can lead to excessive fluctuations during adjustments, while overly tight constraints may hinder the system’s ability to provide optimized solutions.

Performance Review Process:

Regular performance reviews are essential to ensure that the APC system remains up-to-date and continuously improves. Refineries should establish a robust review process to assess the system’s configuration and identify additional optimization opportunities. By periodically evaluating system performance and exploring new features, refineries can enhance their operational efficiency, identify potential areas for improvement, and capitalize on emerging technologies.

Benefits of a Well-Configured APC System:

A well-configured APC system in gasoline blending brings numerous benefits. It enables precise process control, ensuring the production of optimal-quality gasoline within specifications. The high level of automation reduces manual intervention and empowers process control engineers and operators. In lean operational environments, a well-configured APC system can generate significant financial benefits, potentially amounting to tens of millions of dollars annually.

Conclusion:

Maximizing the benefits of APC in gasoline blending requires careful attention to key considerations. Configuring the objective function to align with refinery goals, ensuring accurate parameters and constraints, and implementing a robust performance review process are crucial steps. By addressing these caveats, refineries can achieve precise process control, automation, and substantial financial advantages in an increasingly lean operational landscape.

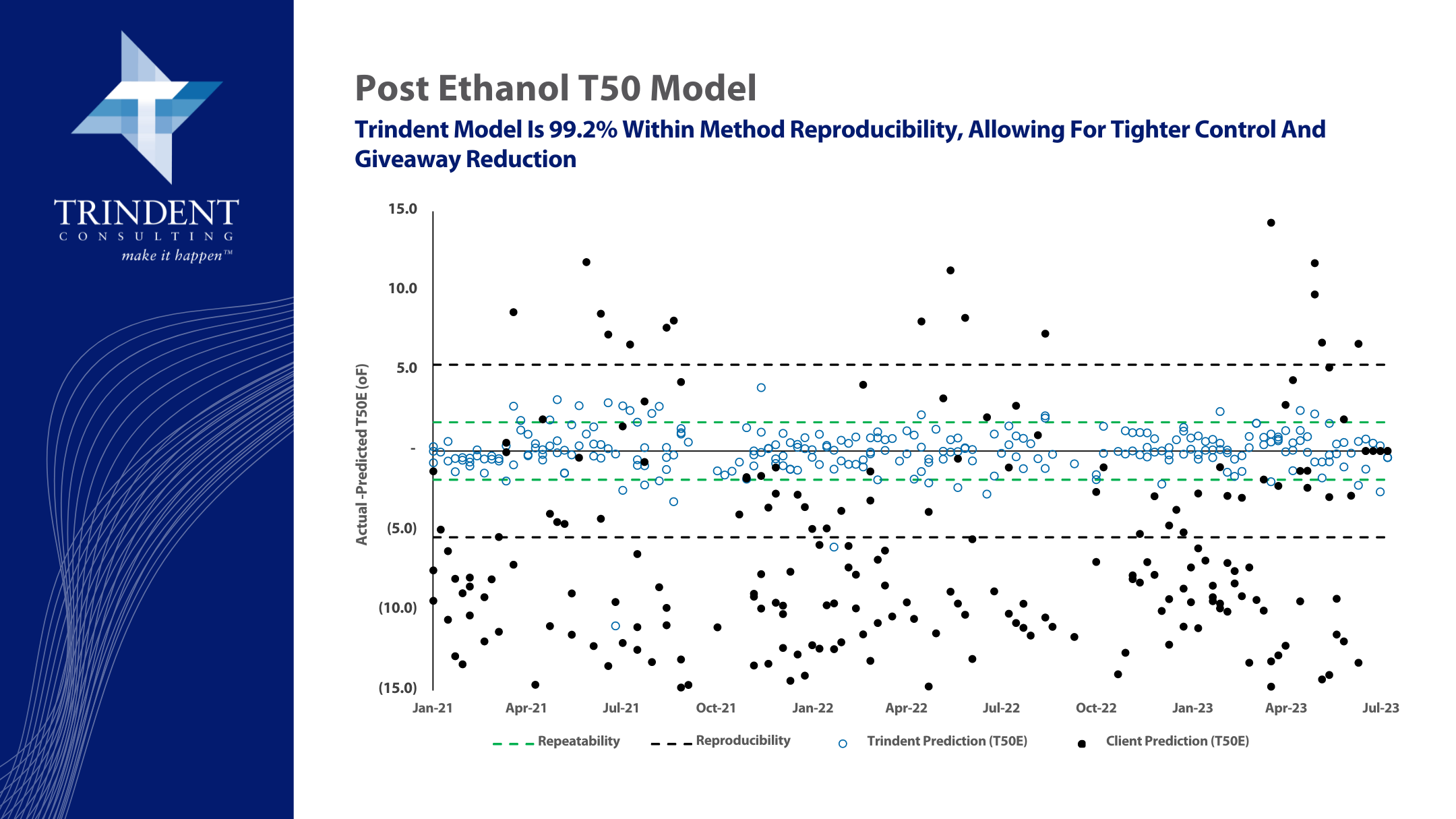

Trindent Develops Accurate Post-Ethanol T-50 Model That Yields $12M in Savings

Trindent is thrilled to share the exciting news of our successful development of an accurate post-ethanol T50 model, marking a significant achievement that has not only resulted in a remarkable reduction in buffers but has also facilitated a 4% increase in butane blending between November and January 2023, translating to impressive financial benefits totaling $12,000,000.

Developing accurate post-ethanol models presents significant challenges for many refineries, particularly when it comes to predicting T50—a key distillation parameter. Ethanol blending exhibits near-azeotrope behavior that severely affects the shape of the E10 distillation curve, making precise modeling complex and demanding.

Moreover, the difficulty in achieving accurate models is compounded by the inherent noise in the data set, such as ethanol blend volume and accurate E0 D86 measurements, which often hinder the development of reliable models.

Despite these challenges, the Trindent team was able to deliver outstanding results to the client.

An achievement like this highlights the importance of precise modeling and data accuracy in optimizing refinery operations and maximizing profitability.

At Trindent Consulting, we’re fueled by a passion for solving the most complex of problems in the energy sector. With expertise in gasoline blending optimization, we help clients achieve significant financial benefits by:

- Developing Accurate Post-Ethanol Models: We develop accurate post-ethanol models, addressing the complexities introduced by ethanol blending and ensuring accurate predictions of key parameters like T50. By leveraging our expertise, refineries can optimize their blending practices and achieve superior fuel quality.

- Reducing Operational Buffers: We understand the importance of maximizing blending efficiency to enhance refinery profitability. We help refineries minimize operational buffers, ensuring optimal utilization of resources and streamlining the blending process for maximum efficiency.

- Enhancing Data Accuracy and Reliability: In an industry where data-driven decision-making is paramount, we excel in enhancing data accuracy and reliability such as ethanol volume %. We empower refineries to make informed decisions with confidence, driving operational excellence and performance improvement without capital investments of software changes of any kind.

- Providing Tailored Solutions for Profitability: Every refinery faces unique challenges, and we recognize the importance of tailored solutions to address specific needs. Our team collaborates with clients to understand their distinct requirements and develop customized strategies aimed at increasing profitability and optimizing refinery processes effectively.

Interested in learning more about our services in the downstream sector? Check out our Energy page to explore our expertise and discover how we drive client success.

Interested in topics related to gasoline blending? Click the buttons below to check out our related industry insights.

“How to Establish a Good Ethanol Uplift Model?”

“How to establish a good ethanol uplift model?” has been a common question when it comes to gasoline blending. With the addition of 10% ethanol to a majority of gasoline products, accurate prediction of the final fuel properties is critical to mitigate margin erosion. With years of experience in blending optimization projects, at Trindent we have developed specific expertise in this area, and here are some insights:

Ethanol Uplift Model Best Practices

Each refinery has its configurations that are developed as a result of the molecules they are making. Therefore, picking the right independent variables to start the development of the model is critical. It starts with understanding the principle of what Octane Number (ON) is, and how this property is related to the chemical molecules inside the gasoline. Typically, a refinery can use as much as 7-8 independent variables, and around 10-15 iterations before finding the perfect model which is not only accurate but also intuitive. The complexity of the model is also important as you want to make it sophisticated enough to provide the accuracy you want, but also simple enough to integrate into the existing system with ease.

Managing Component Distribution

Once a model is developed – the next question would be – how do we optimize it? In addition to adjusting the ON of the neat blend stock (which is often the only approach most refineries take), refineries may take advantage of other property and compositional requirements between to maximize the overall benefit of ON uplift.

Going Beyond ON

While a lot of focus on the ethanol model is about ON, it is imperative to consider other properties that are also affected by ethanol. Therefore, a mature ethanol model system would consider other key properties such as RVP, distillation, and V/L. A good ethanol model system would allow a refinery to achieve method repeatability level giveaway for all their constrained parameters and maximize the benefit from production cost management.

This article was written by KAI Y. WAN, an Associate Principal at Trindent Consulting. Dr. Wan has collaborated closely with multiple business partners in the energy sector across North America and Asia-Pacific, including some of the world’s largest refineries, and has delivered > $300 MM in financial improvements, with typical project ROIs at 500%–1,500% during the first year after implementation.

How Does Butane Affect Gasoline Blending?

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity: Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing: After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How soon in advance does the request need to be placed? How feasible is it to have an additional volume? How is the quality of the product and how to monitor it? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring: This is one of the most critical factors to consider when managing butane – to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

Maximizing Benefits through Advanced Process Control (APC) in Gasoline Blending

Introduction:

Advanced process control (APC) plays a crucial role in real-time analysis and recipe control for optimizing gasoline blending operations. However, to harness the full potential of these systems, users must be aware of key considerations. This article will explore three important caveats when implementing APC in gasoline blending: configuring the objective function, ensuring accurate parameters and constraints, and establishing a robust performance review process. By addressing these aspects, refineries can unlock the benefits of precise process control, automation, and financial advantages while adapting to lean operational environments.

Table of content:

Configuring the Objective Function

Parameters and Constraints

Performance Review Process

Benefits of a Well-Configured APC System

Conclusion

Configuring the Objective Function:

To achieve optimal results, configuring the APC system’s objective function is essential. Refineries must customize the solution to align with their specific refinery posture and economic goals. Often, default settings from initial installation are utilized without considering individual circumstances. Refineries should assess and update these settings regularly to maximize performance and value delivery.

Parameters and Constraints:

The accuracy and timeliness of data feeding into the APC system are critical for effective gasoline blending. Refineries must ensure that data sources are up-to-date, reflecting daily operations and incorporating the latest lab data. Careful attention should be given to the calibration and accuracy of the data. Additionally, refining the constraints is vital to strike the right balance. Overly flexible constraints can lead to excessive fluctuations during adjustments, while overly tight constraints may hinder the system’s ability to provide optimized solutions.

Performance Review Process:

Regular performance reviews are essential to ensure that the APC system remains up-to-date and continuously improves. Refineries should establish a robust review process to assess the system’s configuration and identify additional optimization opportunities. By periodically evaluating system performance and exploring new features, refineries can enhance their operational efficiency, identify potential areas for improvement, and capitalize on emerging technologies.

Benefits of a Well-Configured APC System:

A well-configured APC system in gasoline blending brings numerous benefits. It enables precise process control, ensuring the production of optimal-quality gasoline within specifications. The high level of automation reduces manual intervention and empowers process control engineers and operators. In lean operational environments, a well-configured APC system can generate significant financial benefits, potentially amounting to tens of millions of dollars annually.

Conclusion:

Maximizing the benefits of APC in gasoline blending requires careful attention to key considerations. Configuring the objective function to align with refinery goals, ensuring accurate parameters and constraints, and implementing a robust performance review process are crucial steps. By addressing these caveats, refineries can achieve precise process control, automation, and substantial financial advantages in an increasingly lean operational landscape.

The Importance of On-Site Observations and Witnessing at Refineries

In our capacity as refinery planning and economics consultants , a pivotal facet of our initial assessment involves meticulous observations and active engagement in operations. This approach enables us to firsthand gather information on existing workflows, identify potential issues, and unearth opportunities for value creation. Engaging in discussions with frontline operators and witnessing operations allows us to discern any deviations between planned steps in Standard Operating Procedures (SOPs) and the actual steps performed.

During a recent site visit to a client facility, a significant discovery was made concerning the over-utilization of diluent in the crude blending process to meet the pipeline viscosity requirement. This discrepancy was attributed to a non-ASTM compliant sampling location, methodology, and frequency, prompting a comprehensive review of the blend control process. Implementing our standardized audit and witnessing tools revealed the need for a revised sampling program, leading to substantial cost savings.

For successful site visits, adhere to these guidelines:

1. Ask questions and observe: Engage with frontline workers, formulate pertinent questions, and be mindful of time constraints. This approach helps uncover insights and perspectives, validating information from reports.

2. Document everything: Thoroughly document discussions, take pictures or videos with permission, and summarize insights immediately after the visit. Visual documentation aids in data collection and retention, facilitating the identification of opportunities and implementation of solutions.

Additionally, as implementation consultants, it is crucial to build trust during field visits. Spend time explaining project objectives, emphasizing collaboration, and addressing concerns. Operations personnel should feel integral to the problem-solving process, fostering ongoing dialogue beyond the site visit(s).

Observation and witnessing are integral to Trindent’s solutions, aligning seamlessly with our client's sustainability plan. As refinery planning and economics consultants, we bring a fresh perspective to optimize processes and drive economic efficiency.

Reach out to our team on LinkedIn.

This article was written by Tareq Chowdhury, a Senior Consultant at Trindent Consulting.

Path To Net Zero

Introduction

The 24th World Petroleum Congress (WPC) held in Calgary, Alberta brought over 15,000 visitors and 5,000 delegates worldwide to discuss the industry’s energy transition and path to net zero. The United Nations projects that the world population will reach 8.5 billion by 2030 and 9.7 billion by 2050, leaving billions of people who must be brought out of energy poverty. There is clearly a challenge at a play – how should the industry that is currently supplying approximately 30% of the world’s energy demand lead its energy transformation, while balancing social governance, reliability, economic viability, and a sustainable future?

Key Takeaways

At this year’s WPC, it was encouraging to see innovative technologies and solutions that are in the pipeline to help achieve net zero. One of the presentations that caught my attention was around the application of dimethyl ether (DME) and its recovery technology – while the steam assisted gravity drainage (SAGD) helped pioneer the rise of Canadian oil sands and its direct land footprint is relatively small, the process is costly, energy intensive, and extensively consumes water and natural gas. Most of the water from SAGD operations can be recycled, but approximately 10% must still be disposed and carbon dioxide emissions are at par with combined operations from mining and upgrading. DME displays affinity to bitumen and DME based recovery technology promises to reduce breakeven cost from $40/bbl to $8/bbl, mitigate energy consumption by 90%, eliminate water and steam generation facilities, and increase recovery rate by up to 300%. The provincial government also announced at the WPC that it will invest $7 million into a study conducted by Cenovus Energy on how small modular reactors (SMRs) can be used on oilsands operations. Having also worked in the nuclear industry, this announcement was also particularly interesting as SMRs have been thought to have applications in both public and private institutions. SMRs have a smaller footprint, allowing them to be prefabricated, shipped, and installed on locations not suitable for traditional nuclear power plants.

The examples provided above are two of many initiatives that are being taken by the oil and gas industry. However, the biggest challenge and a common theme that emerges is commercialization. Taking the DME recovery technology as an example, there are no practical applications to date and there is no concrete timeline on when it may be adopted. DME can be produced indirectly from methanol via dehydration reaction and a combination of auto-thermal reformer and direct DME synthesis, but the supply of DME is currently limited. With SMRs, there are still many unknowns surrounding cost and efficiency. Between Canadian Nuclear Safety Commission approval process, public hearings, site preparation, licensing, and construction, it can easily take 10 years start to finish. Even on the most aggressive timeline in Ontario where Ontario Power Generation is building SMRs as part of the Darlington New Nuclear Project, SMRs will not produce power until 2029. Finally, access to infrastructure, limited grid coverage in rural areas, and cost of grid connection for rural electrification can extend the timeline.

Conclusion

So what does this all mean? For realistic energy transition, where energy security, affordability, and economic prosperity can continue to occur, investment in oil and gas must continue. We must stabilize our climate and protect the environment, but in my view, turning off 30% of our energy supply is not the solution. There must be a balance where we hold the government and companies accountable, while working with the industry to implement sustainable solutions.

Reach out to our team on LinkedIn.

This article is written by Kevin Kim, Associate Principal at Trindent Consulting.

Optimizing the Hydrocarbon Value Chain

Overview

Refining companies have a multitude of lucrative coordination opportunities in their efforts to turn hydrocarbon resources into finished products.

In recent years, refiners have suffered with skills shortages, where crucial skillsets left the organization. At the same time, there has been a proliferation of data that makes decision-making more complicated, and after constant reorganization, the inter-departmental siloing of responsibility makes optimization across the total value chain more difficult to achieve.

Any hydrocarbon value chain improvement initiative must first have a clear set of objectives. Some companies seek to optimize working capital, and deployment of liquid inventories. Others seek to configure for optimal margins, while others are most interested in operational flexibility, and ensuring maximum throughput from refining assets.

Organizational Participants

In our view, there are as many as ten discrete departments that must work together to maximize the total hydrocarbon value chain. In general terms, they are:

Trading – Product exchange for alternatives to production, and getting the right crudes and feedstocks to maximize added value.

Planning – Identifying decision drivers through optimization including crude selection, operating conditions, stream dispositions, product blending and demand allocations;

Scheduling – Translating the planning decision drivers into a feasible and achievable set of execution instructions while minimizing logistics cost;

Process Engineering – Providing rigorous, technical process insight and direction that informs operations and planning and scheduling modelling requirements;

Refinery Operations & Maintenance – Executing safe, reliable and optimal production and providing current information that enables well informed plans and schedules;

Logistics – The movement of refined products to their final destinations efficiently and by the lowest practical cost.

Distribution – Placing product in quantity into the highest margin markets;

Production Accounting – Managing hydrocarbon losses and providing quality reconciled “actual” data;

Master Data Management – Providing a unified quality data for performance analysis;

Performance Analysis – Providing measurement and visualization capabilities that facilitate collaborative enterprise optimization and management of past, present and predicted performance.

The Functional Landscape

Below is a map of the functional landscape that illustrates some of the opportunities that are available for optimization at any given time:

Starting Points

Ensuring a uniform, latent and accurate set of data is helpful. Often outdated prices, incentives, and inventory positions make ‘optimizing for yesterday’ a phenomenon. We typically will commence an improvement project with a focused effort on making the refinery material balance more accurate and trustworthy. Further, there are number of techniques to improve the physical visibility of crudes and products in transit, giving them more of a real-time.