Inventory as a Tool – A Healthcare Perspective

For

healthcare organizations, inventory can be an important and powerful tool for

controlling effective equipment management programs and providing better access

to, quality of, and utilization of medical devices.

Accurately managed inventory can also be used for forecasting, developing budgets, performing risk analysis, risk management and mitigation, developing replacement and disposal practices, maximizing optimal safety stock inventory, and more. The insight it provides into an organization’s financial state allows for confident business decisions that translate to savings.

As

healthcare organizations face increasing pricing pressures, one area where

inventory can specifically be used as a tool to uncover savings is in assessing

the benefits of equipment standardization.

Using Inventory as an

Assessment Tool

Medical

equipment has significant impact on healthcare costs. For healthcare providers, equipment

standardization is one way they can reduce direct and indirect expenditures –

and equipment inventory is a key metric to finding and realizing the financial

benefits associated with standardization.

In

assessing their medical equipment costs, healthcare organizations take a number

of measurements into consideration; the number of SKUs on hand, cost per SKU, cost

of inventory space, failure rates of equipment, use frequency of parts, variability

between different pieces of equipment, cost of equipment maintenance, and the

cost of training users and technical maintenance staff on using various pieces

of equipment.

Much

of this information is either directly or tangentially gathered from equipment

inventory, and it gives healthcare organizations real insight as to where they

can streamline and standardize their operations in order to reduce costs.

The Benefits of Equipment

Standardization

Equipment standardization allows organizations to

realize benefits like a reduction of equipment SKUs;

a need to have fewer parts on hand; a reduction in training needs; having less

supporting documentation to process; simplified vendor management; and the advantage

of increased bulk discounts.

Put

together, these benefits add up significant bottom line savings from reduced equipment,

parts, labour, and space costs.

How

Trindent can Make It Happen

Medical equipment inventory is so much more than a list of an organization’s assets. If properly utilized, it can provide a foundation for healthcare equipment management, which in turn can be used to find significant bottom line improvements. This is where Trindent’s healthcare consultants can help.

With deep healthcare industry knowledge, Trindent understands its specific challenges, and can implement changes to deliver sustainable savings. Working collaboratively with our clients, Trindent takes a detailed look at inventory points to evaluate and establish correct levels at the right locations.

Click here to find out more about how Trindent can help your healthcare organization utilize your inventory to realize the benefits of equipment standardization.

The Cost of Outdated Processes

An outdated or inefficient process can have a greater impact

on an organization than management realizes.

Previous articles in this series looked at the challenge of identifying inefficient processes. This article will discuss the impact on organizations if they don’t make the effort to root inefficiencies out and correct them.

Increased Costs

One of the most noticeable effects of an inefficient

process is an increase in costs, driven

by factors like longer processing times, elevated labour costs, lower direct

labour utilization and overtime, increased inventories with lower turns,

increased material consumption, material loss, high rework levels, multiple and

unnecessary touch points and similar factors.

Without identifying and addressing the outdated

processes that lead to these inefficiencies, an organization may be leaving hundreds

of thousands of dollars on the table.

Lower Service Levels

Another result of a sub-optimal process is reduced

service levels. Whether the process

services an external customer or an internal downstream department, longer

processing times will inevitably trickle down and affect overall company

performance. In addition to driving

higher costs, increased service levels seriously impact the competitive

position of the company.

Some external service

levels can be effectively benchmarked against industry

standards and trigger inquiries into efficiency when the company fails to

operate at a certain level. With

internal processes however, it is often impossible to gain insight about the internal

metrics of competitor companies in order to be able to compare apples to

apples.

Lower Revenue

Inefficient or outdated processes simply cannot produce

the same amount of customer value per unit of time as their streamlined and

efficient counterparts. In addition to

reducing the profitability of what is being produced, outdated processes

may lead to reputational risk and result in missed sales because they hamper an

organization’s ability to meet demand.

Result: A Lower Competitive Position and A Higher Risk

The competitive position of any business is determined by the amount of value it can generate and its ability to capture that value. The figure above shows the effects of the outdated processes discussed above. The inefficiencies exert dual pressure: Downward on the value of the product or service, and upward on cost of providing it. The overall effect is a reduction in profitability.

A major risk associate with running an organization that

has low competitiveness and profitability is the financial difficulties they

will face when market conditions worsen. As a direct consequence of being in a weaker

competitive position with lower profits, an organization may find itself underwater

in situations where its competitors manage to weather the storm.

Delaying evaluating existing processes with a

systematic approach may prove detrimental to long-term success.

Click here to learn more about how Trindent Consulting can help you evaluate and correct your outdated and inefficient processes.

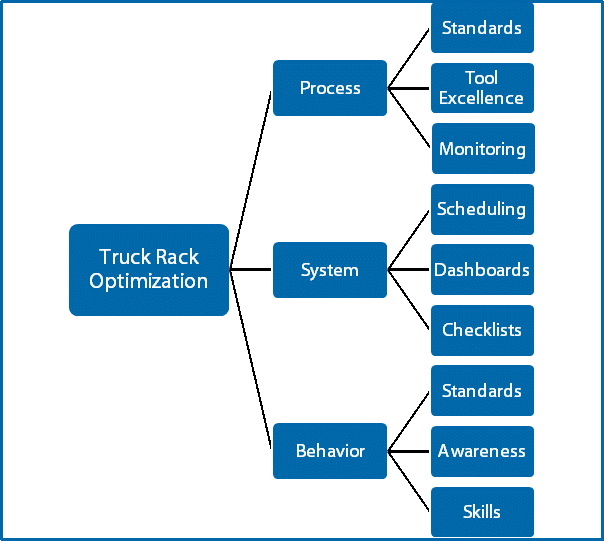

Truck Rack Process Optimization: A Case Study in Refinery Performance

Performance consulting, by

definition, deals with the integrity and effectiveness of processes. At Trindent Consulting we know that process effectiveness

is impossible to achieve without also addressing two important aspects of every

organization: The system, which

measures and guides the process, and the behaviour of process

participants, which is a direct response to the system.

This is true with the simplest of the processes in small companies and becomes even more important with the increased complexity of medium to large organizations. Oil refineries fit the category of a “complex organization” and have been an area where Trindent Consulting has consistently brought significant value, working with various processes and components, saving our clients millions of dollars without requiring any capital expenditure.

Refining Refineries

Truck Rack operation is a good case study to illustrate the importance of an inclusive approach to process management. It may be considered one of the less complex processes in a typical refinery, but it provides ample opportunity for improvement if the right approach is followed.

Refineries produce many types of products, including various types of gasoline, such as 83 ON and 91 ON. The Truck Rack uses these as ingredients in its recipes to produce gasoline types supplied to the end user. The recipes are well known, the math behind them is straightforward, and measurement equipment is in place to ensure accurate performance. However, Trindent in its work with quality giveaway reduction has repeatedly been able to help refineries achieve significant savings by reducing octane give-away and optimizing the blending process – including the theoretically simple Truck Rack process.

Secret Ingredient

This is achieved by critically evaluating existing components of the process, system, and behaviour; and then addressing any areas of divergence from industry best practices. Combined with proprietary benchmarking and a robust effort to develop solutions uniquely tailored for every client, the approach yields a significantly enhanced competitive advantage. A unique benefit of using Trindent’s approach is that no capital expenditure is required in achieving lower octane give-away numbers, which then translates directly into significant refinery margin improvement.

Another added benefit for

refineries is that the improved accuracy in blending and quality control allows

them to stay away from failed recipes, which arguably have even larger impact

on a refinery by opening it to the risks associated with poor product quality,

re-blend opportunity costs and dissatisfied customers.

Hidden Opportunities

Regardless of how straightforward a

process may seem, there is always ample hidden opportunity for improvement

without capital expenditures. All that’s

required is a methodical and

systematic approach to addressing all the components. Trindent Consulting specializes in conduct

assessments to uncover opportunities to improve refineries’ operations to

best-in-class performance

Hydrocarbon Loss: Regaining Control

Hydrocarbon Loss costs individual refineries millions of dollars per year and occurs daily in refinery operations when improper systems, processes, and behaviours are in place. Best-in-class targets are under 0.25% loss while under 0.5% loss is considered an achievable target for the average refinery. If your refinery is performing worse than these targets or, worse, is operating in the dark, don’t worry, a solution exists – Hydrocarbon Loss Control Programs.

A Hydrocarbon Loss Control Program is a set of measures that can be implemented to systematically reduce refinery Hydrocarbon Loss. A key component of the program is Mass Balance. At a refinery, there are various temperatures, pressures, and chemical transformations happening throughout the process that make measuring on volume ineffective. As a result, mass – which can be neither created nor destroyed – is used to identify where hydrocarbon loss or gain is occurring.

An effective Mass Balance program will identify all refinery fence line inputs and outputs to identify known losses and potential causes of unknown losses. In a previous article, we discussed the common causes of Hydrocarbon Loss. At Trindent, we use a structured approach to prevent these common causes, regain control of Hydrocarbon Loss, and achieve mass balance.

How

Do We Reduce Mass Balance Loss?

Mass balance relies heavily on accurate data; however, at a refinery, there are many possible sources of error. One way our team of Hydrocarbon Loss Consultants helps reduce mass balance loss is by improving measurement accuracy at the refinery fence line. With more accurate data, refineries can use data-driven decision making to eliminate the root causes of loss. Part of our mass balance programs focus on:

- Meter Troubleshooting – First and foremost, it is important to determine if the proper meter is in place for measuring the desired characteristics considering the process and environmental conditions. Secondly, meters need to be proved at the right frequency and with the right conditions in order to be meaningful. We use meter proving check lists and control charts to determine whether this is occurring.

- Tank Gauging – There are many methods for storing

hydrocarbons: tanks, rail cars, marine vessels, shore tanks, etc. Each method

has its own sources of error when measuring the quantity of hydrocarbon. For

example, tanks can have tank stratification or shifted bottoms which reduce the

accuracy of measurements. Marine vessels can be subject to dynamic ocean

conditions which can make for difficult measuring conditions. We use our

knowledge and standardized check lists to troubleshoot and reduce these errors.

- Measuring Sediment and Water

(S&W) – Understanding

the sediment and water content allows for the refinery to properly account for

these non-value added intrusions. However, refineries do not always follow

measurement best-practices and can obtain erroneous results. For example, when

measuring suspended S&W it is important to grab samples from the top-down

to prevent contamination. Another common error is to not use a demulsifier or

to use expired demulsifier which greatly reduces the ability of a centrifuge to

separate water from the crude sample. We use standardized check lists and

measurement analysis tools to obtain representative samples and determine when

action is required.

At Trindent, we focus on tangible results and showing improvement through data. Our data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

To learn more about how Trindent can Make It Happen in your company, reach out to our team on LinkedIn or through our Contact Us page.

The author of this article, James Greey is a Senior Consultant at Trindent.

Ten Principles of Clear Statements For Business Writing

Good writing aims to communicate a clear

message. In business writing especially,

brevity and clarity are key to communicating effectively and getting buy-in

from the key stakeholders in your audience.

The last thing a writer wants is to leave their audience wasting time

trying to decipher complex text or dig through a clutter of unnecessary words.

Given the need for precision in business writing, a set of ten “how to” principles was designed by Robert Gunning, the creator of the Gunning Fog Index. Gunning believed that writers “need a set of principles that strike at the root of Fog …to serve as a useful guide to clear thinking, and thereby to clear writing”.

Ten Principles of Clear Statements

- Keep sentences short

- Prefer the simple to the complex

- Prefer familiar words

- Avoid unnecessary words

- Put action in your verbs

- Write the way you talk

- Use terms your readers can picture

- Tie in with your reader’s experience

- Make full use of the variety

- Write to express, not to impress

Not all principles will apply in everything you write but using some appropriate combination of the principles will help you create documents that paint a clear and concise picture for your reader. In writing materials in the healthcare consulting world, for example, principles 7 and 8 can be indispensable in gaining support from key stakeholders.

Use Terms Your Reader Can Picture and Tie in With Your

Readers’ Experience

Healthcare professionals use very specific language in their work. In producing documentation for a healthcare consulting engagement, using terms your reader can picture, and using their experience as context, makes a substantial difference in writing concisely and keeping the reader engaged.

Take for example the terms “wheels out” and “wheels in”. To the average person, these will read as something to do with car repair, or possibly an arrival time. But to a healthcare professional, they will instantly paint a picture of a patient bed rolling into or out of an operating room and will start them thinking of turnaround times associated with surgery. Best of all, the use of that terminology requires no explanation, thereby reducing the length of the document being read.

Using principles 7 and 8, in this case, created a powerful and clear message with minimal words.

Keep This List with You

Not every one of these principles is going to apply to every business document, but the ability to use precise language tailored to your audience is key to increasing your likelihood of getting stakeholder buy-in. To begin writing clearly and keeping your reader engaged, keep this list with you.

FOCUS PDCA - A Lean Tool For The Healthcare Industry

With a core objective of maximizing customer

value while minimizing waste, Lean management principles are widely used

in most industries, and healthcare is no exception.

FOCUS PDCA is a Lean tool developed by the Hospital Corporation of America to specifically address the complex challenges the healthcare industry faces from increasing quality demands and continued pricing pressures. The tool provides a structure to guide problem-solving and process improvement activities by establishing a comprehensive analysis, response, action plan, and feedback loop that ensures success.

FOCUS PDCA is comprised of two

components – one used to identify and the other to implement.

FOCUS – Identifying the Process

Improvement

FOCUS is an acronym whose steps help

to simplify the process of identifying the area of a healthcare organization that

requires improvement, bringing together a team capable of achieving that improvement,

and selecting the best possible solution to implement the improvement.

Broken down by its parts, here is

how FOCUS works:

Find a process to improve – Identify the process improvement opportunity

Organize the effort to work on improvement – Identify who the key stakeholders in the process are and

who should be part of the improvement team

Clarify current knowledge of the process – Leverage stakeholders’ input to ensure that all information has been gathered and there is a consistent mindset on both the process improvement opportunity and the direction of the proposed solution

Understand process variation and capability – Identify

potential process variations, small or large, and their possible effects on

change implementation.

Select a strategy for continued improvement – Select an implementation strategy, outline the expected results, and identify success criteria using the information gathered from the above steps as input.

PDCA

– Implementing the Solution

Once the FOCUS process has

identified the area for improvement, brought together a team, and found the

best possible solution, it’s time to implement that solution.

The PDCA portion of the tool

identifies the process to successfully implement the changes and verify that

the desired result has been achieved.

- Plan – Create an action plan for implementation, including a list of required steps, the implementation schedule, ownership, and responsibilities, and desired outcomes.

- Do – Start implementing the plan, following the Plan steps, and adhering to the schedule to stay on track.

- Check – Take measurements against the success criteria set when selecting the strategy to ensure the implementation is progressing as it should be.

- Act – Based on Check results, determine the process was successfully changed; or return to the beginning of the cycle if it did not meet goals.

A

Practical Application

Although developed specifically for healthcare, the FOCUS PDCA tool covers all the basic components needed for improvement in any business process, and over the past 12 years, Trindent Consulting has successfully applied lean process management concepts in healthcare, energy, and financial services.

Click here to learn more about how Trindent can help healthcare organizations tackle their unique challenges.

Time Is On Our Side

"Time is on our side…” proclaimed Mick Jagger of the Rolling Stones. Depending on how easily you recognized that song, you may or may not agree and there may or may not be much you can do about it. However, if you are running back-office operations more than likely time is not on your side. The good news is there is more you can do to improve that situation than you think.

The front office or contact center has, for decades, been the standard-bearer for measuring and managing time and their employees' positive or negative relationship to it. With the toolsets available today, literally not a second goes by that is not measured, categorized, and assessed.

In most back-office environments, the focus is predominantly

on the time it takes to complete an end-to-end process. How long it takes to submit

an application, process a claim, or update a client’s address or policy

beneficiary, for example. Often broken down into a series of individual steps

or tasks, managing turnaround time for these processes down to the minute is

critical to the company’s bottom line as well as the all-important customer

experience. Detailed examination of end-to-end processes can, and very often do,

bring hidden opportunities for improved efficiency and cost savings. Trindent can

help with that.

An area where many back-office environments often fall short

goes beyond process management and looks at broader time and resource

management. Outside of the processes you are so closely managing, how are your

employees spending their time? The answer – and even just your ability to

answer the question – may surprise you.

Most office production environments have assumptions built

into their budgets to account for daily non-discretionary unproductive time

like breaks and lunches. Often, there are several other activities, perhaps

more discretionary in nature, like meetings, follow-up on pending cases,

answering email or voicemail, 1 on 1 coaching, training, etc., that occur on a

daily or weekly basis that are not always itemized in operating budgets. All

these activities, discretionary and not, can add up to 30-40% of an 8-hour day,

sometimes even higher. Moreover, you are

very likely paying for overtime as well because somehow processes

and tasks are not getting completed as expected.

Let’s look at the math, shall we?

Typical fulltime day = 8 hours or 480 minutes

Breaks (often 2x 15 minutes) = 30 minutes = 6.25%

Lunch = 30 minutes = 6.25% (Likely unpaid, but time is time)

Follow-Up = 30 minutes = 6.25%

Email / voicemail = 30 minutes = 6.25%

Daily Team Meeting = 15 minutes = 3.125%

Other meetings = 60 minutes = 6.25%

Total Non-Production Time = 195 minutes = 41%

Getting a clear accounting of all these items provides a

much more effective picture of what expectations need to be in place around how

employees are spending their day.

That said, assumptions will only carry you so far. It is in

the tracking of the actual activity where the greatest opportunity lies. The

reality is meetings go long, employees linger over breaks and lunches, follow

up takes longer than expected. What about when your employees arrive and leave

work? Are they arriving on time or leaving early? Suddenly that 41% assumption

starts looking more like 50%. On the other side of the coin, what if you find your

assumptions are inflated but you are still seeing the same productivity? Where

did that time go? (Oh, and did I mention overtime?)

“WE ARE NOT A CALL CENTRE!” is a familiar mantra. Couldn’t

agree more! If you were a call center, we would be pulling out a much larger

magnifying glass. But you do have resources, often hundreds of them, that need

to go through their day in a time sensitive manner. You need to be able to

account for their time.

But don’t despair! Depending on the platforms and tools you have already deployed, a variety of approaches can be taken to make active time management an integral part of your day to day operations. And Trindent can help with that too.

The author of this blog - Paul Camrass is a Senior Consultant at Trindent.

Image courtesy of macrovector

Some Like it Smart: Two Different Strategies for Expense Reduction

By Adrian Travis

The recent COVID-19 outbreak has resulted in some very unprecedented actions on the part of world governments and businesses. The only certainty seems to be uncertainty itself, and it’s not yet known how long the situation will last or how damaging its impact will be. Simultaneous interruptions to both supply and demand for goods and services will test the resilience of companies in varying ways. Downturns tend to elucidate the differences between businesses that are strong and prepared, and those that are weak and reactionary.

One unassailable fact is

that ALL businesses will need to shore up their financial performance and

balance sheets. Most cost-cutting

initiatives are indiscriminate and value-destroying in the long run, while a

more targeted approach is always a good course of action for the short, medium

and long term.

Value

Destroying Ways to Impact the Expense Line

During

difficult times, blanket edicts like ‘all cost centers must reduce spending by

15%’ often look like acceptable business decisions but are bad long-term

ideas. Companies fall into several

traps:

1. People are expensive and visible – staff reductions tend to be indiscriminate and expensive if they’re done in a haphazard way. The morale of those that remain is typically problematically impaired. In the long run, it may cost even more to re-hire when situations improve. A great question to ask is: ‘knowing what I know about a given employee – would I rehire them today.” If the answer is yes, then except in a dire situation, making an unfortunate employment decision will typically be a value-destroyer.

2.Abandon long-term projects - Focus on ‘urgent problems and forget the rest’ while sacrificing innovative programs which might sound advantageous in the heat of the moment. If it’s a project that is critical to long-term success, avoid the reactionary tendency to abandon it. Remember, you only regret the things you don’t do.

3.Cut corners – By reducing service and quality attributes, companies inadvertently cause harm to their competitive position. Sometimes companies switch to less-expensive business partners or suppliers only to incur expensive transitions back and forth. Most harmful of all is engaging in an outright refusal to pay invoices or using thinly veiled subterfuge to avoid payment for well-delivered products or services. This final instance has the effect of compromising your business network permanently.

Smart

Strategies for Expense Reduction

Hazard Expenses – These are typically ‘costs of doing business’ hazards like excess, obsolescence, expiry, damages, overages. Making the distinction between ‘good’ and ‘bad’ costs is essential for prioritizing improvement initiatives.

Hidden Losses – Trindent’s consulting practice is almost exclusively focused on ensuring that unnecessary quality isn’t given away in a business process. As well, consider if you are getting full value for the inputs that you pay for. A refinery, for example, typically receives 0.7% less crudes and feedstocks than is paid. The same refinery may also be paying for expensive sediment and water at the full price of crude oil.

Productivity – Impacting human performance by eliminating unproductive activities, rework, waiting, double-handling, planning or other forms of waste is always a viable strategy to compete better. Even in the best of times, Trindent has found that average human productivity in a bank or insurance company processing center is only 43%. The significant opportunity associated with the remaining 57% of ‘lost time’ can be tackled in order to shore up a business’ expense performance.

Cash Flow – Working capital tends to expand significantly during downturns, which forces sometimes counterintuitive decisions to be made on a variety of fronts. Structured working capital initiatives should focus on optimizing receivables, inventories, and payables. There are a number of innovative strategies and tactics that can give a company millions of dollars in free-flowing cash from operations.

Conclusion

While the impact of the business interruption we face is not known, it’s always a prudent idea to shore up a company’s financial position. Episodic cost-cutting initiatives typically undermine a company’s long-term success prospects. However, the best-performing companies are not sporadic cost cutters, but are seeking to drive every-day improvement in the right areas, in the smartest possible ways.

“Where Is My Octane ?” – Recognizing Benefits in Blending Optimization Refinery Projects

By Anas Dabbakh

Refineries are a crucial step between raw crude oil and getting the gasoline into your car. There are several chemicals that have to be blended together at the refinery, such as octane, RVP, V/L, T50, etc. in order to create gasoline.

It is important to understand that oil and gas quality giveaway reduction cannot be successfully sustained without some specific changes to refinery planning, gasoline scheduling and execution processes. For example, reduction in octane giveaway will increase the refinery octane pool. Without taking actions to re-balance this pool, the refinery eventually will start giving it away again.

Having gone through multiple blending optimization and quality giveaway reduction projects, I have realized how such projects are beneficial at the refinery. And this is a very interesting question – where did all the saved octane-barrels go?

There are several strategies the refinery can undertake to “tie-up” saved octane barrels, and make giveaway reduction last:

Change blendstock purchasing from high-octane valuable to lower octane blendstocks.

This could mean changing high-octane valuable to low octane natural gasoline or butane. This may also have additional benefit from increased gasoline production, thereby lowering cost per barrel.

Lower own production of high octane or high value components.

For example, lower Reformer unit severity, or change to a different (less efficient) catalyst, etc.

Consider sales of high octane or high value components in the open market.

If lowering high value components cannot be achieved, or has limitations, then sales of this component in the open market can be considered. Obviously, market conditions should be favorable to such component sales.

Shift production profile

Shifting your production profile to more premium gasoline will consume more octane.

These strategies can be used in combination. Their successful implementation requires close coordination between production planning, scheduling and lab testing.

The Daily Check to Great Performance

Managers have the very important job of

guiding their teams to meet – and try to exceed – a certain level of

performance. For an organization to

fully realize the benefits of the process, system, and behavior improvements

that are implemented as part of Trindent engagements, managers must actively

lead their teams both through and after the change implementation.

In past engagements , Trindent has observed clients who lacked a process to track, review or enforce team productivity and targets, and in these situations, the first recommendation we made was the introduction of a daily schedule check. In this end-of-day meeting, managers were coached to implement a “result, schedule, people” oriented framework as an ideal way to have short and concise result-oriented discussions with their teams. This allowed managers to have ongoing visibility to team performance, and a quick way to ascertain the causes of underperformances and how to correct them to get productivity back on track.

Let’s look at the daily schedule check, and

the three components that make it effective and concise.

Results

The first component of the daily schedule

check is for staff to update their manager on what was completed that day. This initial part of the update is important to

enable managers to determine how members of their teams are performing, and whether

goals and targets need to be adjusted going forward. If a high performing employee continuously exceeds

their target, they may need more challenge, and can also potentially be utilized

to train or mentor lower performing team members. Conversely, if a low-performing employee

continues to fall short of their target, being able to see their daily results

gives their manager ongoing visibility to poor performance and an opportunity

to investigate the underlying issues of the performance in order to quickly resolve

it and turn it around.

Schedule

In the schedule portion of the update, team

members report on tasks that have been started but are not complete. This allows a manager to gauge variance

against expected results, and determine whether their team has a handle on the

situation given that variance. Some

amount of variability is normal in any role, but continuous variance in results

is a signal for the manager to step in and discuss options to remedy the

situation in order to enable staff to once again reach their objective.

People

The people section of the update is to discuss

any employee-related obstacles that are preventing the meeting of objectives. For team members, this is the perfect

opportunity to share updates about a subject that’s usually difficult to bring

up. This is also an important component

for managers, as it’s their responsibility to resolve issues with any employee

performance that may be affecting the output of others.

Conclusion

“Active management should be a day-to-day activity highlighted by simple feedback given more frequently – feedback is less effective as time elapses between performance and feedback.”

With this simple framework – results, schedule,

people – managers can use the end of day schedule check to effectively manage

employee performance and provide support when variances occur. Its daily cadence allows for ongoing

visibility to results, and gives managers to ability to quickly make

adjustments and changes so that variances don’t become the norm.