Extracting Value from Daily Review Meetings

Daily review meetings are an integral part of the of the active management initiative that organizations hire Trindent Consulting to implement. The meetings have a two-pronged purpose. They give managers a daily opportunity to review KPIs on the team dashboard to gauge progress against targets, and they function as an open forum discussion for staff to contribute ideas, share best practices, and bring up challenges they may be facing.

The first component is straightforward – managers preform the dashboard review while staff listen and absorb. However, in most organizations, the second component of the meeting is a challenging one. When staff are asked to share, the outcome is often not optimal. Staff can be reluctant to speak up if they feel they’re not being heard, or if they believe they can get away with not contributing or being accountable.

Without input from staff, the daily review meetings lose their value. They become an exercise in one-way dashboard review, something that doesn’t require a meeting to be held at all.

Here is where another important tool that Trindent advocates comes into play – the Action Log. When used as part of daily review meetings, it allows managers to instill a sense of engagement and accountability into their staff, thereby maximizing the value of the meetings.

The Action Log Is More Than a Tracker

The action log is more than just “meeting minutes”. It’s a tool that allows managers to record, prioritize, and keep track of the takeaways generated during the meetings in order to keep their team accountable; and it functions as a listening tool to drive engagement.

Unlike meeting minutes, action logs don’t document every discussion point in each meeting, but rather keep an on-going rolling record of the objective to-dos that come up at successive meetings. Each action is assigned an owner and a due date, and the logs are reviewed at the beginning of each meeting to go over what’s been completed since the last session, and at the end of the meeting to confirm new items that have been added.

This level of constant attention to the action items serves to not only ensure that no task slips through the cracks, but it promotes accountability of each staff member to complete their assigned tasks, as anything that’s outstanding will be brought to the attention of the entire team.

The second function of the action log is as a management listening tool to drive team engagement. A common sentiment from employees is that they feel their “voice is not heard” and that “managers don’t listen”. When actions are added to the list and read back to the team at the end of each meeting, it shows the team’s manager has listened to, and understood, everyone’s ideas. By documenting these next step actions, team managers are driving engagement by imparting importance and giving time to the ideas and questions their staff have brought forward.

By using this valuable tool, managers can empower their teams, drive accountability and engagement, and get maximum value from daily review meetings.

Management Consulting in Healthcare

In their work, management consultants use their skills, knowledge, and expertise to enhance management and organizational performance by driving process improvements. The changes they generate and implement bring value to a company through proactive and reactive improvement efforts that can help any organization course-correct its operations and obtain higher standards of performance and efficiency.

What Is Healthcare Consulting?

Healthcare consulting is based on the same principles used in other areas of management consulting to help identify and implement improvements. But healthcare is a complex industry and implementing change in these organizations is often more difficult than in other sectors.

There is an extra level of challenge for consultants in healthcare because it encompasses a wide area; from the smallest hospital operating rooms to the largest global medical manufacturing giants. Healthcare consulting can mean you’re spending your days at the head office of a hearing aid manufacturer, observing a medical devices warehouse to find supply chain improvements, or donning scrubs in a hospital’s sterile environment to analyze turnaround times for surgical equipment.

The Need for Focus

To be successful in the healthcare industry, and to effectively tackle its unique complexities, consultants need to be highly specialized and have deep but focused expertise. At Trindent, our focus falls on these three areas:

Medical Devices

This is a rapidly developing area of healthcare, one that’s increasingly facing the need for improved manufacturing and cost reductions to remain competitive while still adhering to strict industry standards. In this sector, Trindent Consulting has helped clients with supply chain optimization, customer service improvements, and rapid procurement practice responses to eliminate unnecessary losses.

Hospitals

Facing financial constraints and healthcare reform, hospitals are constantly feeling the pressure to do more with less while still trying to improve patient care and safety. This is often a difficult and overwhelming situation, but another area where Trindent has proven experience. We work with hospitals to optimize their facility effectiveness so they can keep their focus on the wellbeing of their patients.

Pharmaceuticals

The complexities of this industry sector are no surprise. With zero-error requirements, new sterilization regulations are putting a strain on the supply chain management efforts of many pharmaceutical companies. Leaning on the experience of healthcare consultants like Trindent to help manage the ever-increasing intricacy of their supply chains allows pharmaceutical companies to improve their productivity and keep their operations running optimally.

Unique Ability to Advance Healthcare

Within these three areas, healthcare consultants have the ability to help advance the industry forward. Using management consulting services allows organizations in the healthcare industry to reach higher standards of performance and efficiency so they can continue to drive progress and innovation.

Trindent specializes in assisting healthcare companies. We understand that pricing pressures, healthcare reform, and complex routes to the ultimate point of care are creating unprecedented challenges for the industry, and we use our deep industry knowledge and experience to help you deliver meaningful and sustainable results.

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

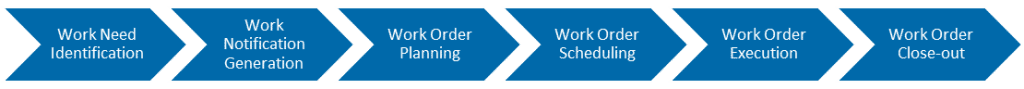

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenanceefforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

To learn more about how Trindent can assist your refineries to avoid the pitfalls of a work management process, reach out to our team on LinkedIn or through our Contact Us page.

The author of this article - James Greey is a Senior Consultant at Trindent.

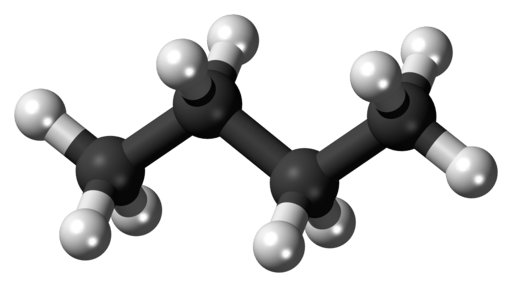

Minimizing Refinery Giveaway Through Butane Management

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity: Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing: After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How soon in advance does the request need to be placed? How feasible is it to have an additional volume? How is the quality of the product and how to monitor it? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring: This is one of the most critical factors to consider when managing butane - to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

At Trindent, we have the expertise to improve the utilization of butane as well as other solutions to reduce giveaway in gasoline blending. Our experience over the last years shows that significant Year-on-Year improvements can be achieved in butane inventory management (up to 100% - 400% additional butane inventory) applying our methodology of changes in systems, processes, and behaviors without any capital investment.

This blog's author - Dom Alvarez, is a Senior Consultant at Trindent Consulting.

Butane Tank image courtesy of Terry Joyce via Wikipedia commons

Operations Consulting in a Remote World

In response to the ongoing COVID-19 outbreak, companies around the world are facing new challenges requiring innovative solutions to weather this storm. For many organizations, this includes a rapid transition to a work-from-home environment. Some were already well on their way to enabling their employees to work remotely, others were not as prepared. As we all come together in our respective home offices to overcome this pandemic (with huge appreciation to those in front-line essential service roles), how can an operations consulting firm like Trindent continue to deliver results to their clients? Below, I share two areas of success and one challenge our team experienced over the past three weeks implementing long-distance solutions in the insurance industry.

Success - Communication

Under normal circumstances, the success of engagement is built on a foundation of thorough communication. When your team is spread across four time zones and 6,000 km working out of makeshift home offices, this is doubly true. To maintain project continuity and ensure our team priorities remain aligned, we ramped up digital communications. Overall, these practices helped deliver ongoing success from a communications standpoint:

- Morning Huddles: Daily team check-in to discuss priorities for the day ahead

- Wash-Up Call: End of day review of actions, roadblocks, and next steps; includes key client stakeholders for enhanced transparency into our team’s approach

- One-on-Ones: Weekly 360° feedback sessions to understand what’s going well, what needs improvement, and how I can better manage the team and the project

- Tri-Weekly Touchpoints: 20-minute meetings held M-W-F with key client stakeholders to discuss current progress and understand any of the team’s concerns

- Humour: Historically, I’ve never been one to forward jokes from friends and family to colleagues, let alone to clients. More recently, I’ve loosened my stance on this and don’t plan to turn back. Please direct your best client appropriate jokes to tguyette@trindent.com

Challenge - Technology

In the time we need it most, one of the most significant challenges I’ve faced in the past few weeks has been on the technology front. Understandably, networks are overloaded and IT departments are fighting to respond to unexpected demands. Here is a short list of technology-related issues and attempted workarounds:

- Issue: Calls occasionally drop, video chat is delayed, long file transfer times

Solution: Use alternative software packages where available. Microsoft Teams has proved reliable so far

- Issue: Difficulty conducting a remote process observation (full day side-by-side observation) of the client’s contact center due to network restrictions preventing screen-sharing

Solution: Analyze pre-recorded calls including screen-capture, combined with workforce management software to monitor occupancy rate, as well as supervisor interviews to understand management effectiveness and operational performance

Success - Implementation

Resistance to change is a trademark challenge of any consulting engagement and one that can be the most difficult to overcome. It’s not surprising that employees are reluctant to change their way of doing business when an outsider shows up at the office claiming to have a solution for their problems. Now, the outsider can’t even show up! Some of the ways our team has found success in implementing solutions without stepping foot on-site:

- Method Change Workshops: every method change (solution) we recommend includes an accompanying workshop. We clearly define the problem it addresses, the qualitative/ quantitative impacts, and the proposed solution(s) with a cost/benefit analysis. Workshops are interactive sessions involving managers and SMEs to verify our assumptions are accurate, and that our implementation plan makes sense for the client.

- Prototypes: Many solutions require a proof-of-concept to demonstrate feasibility. Our team recently developed a system to track errors and reduce the time required to process insurance applications. Feedback from front-line staff determined the new system was slower than the original. We listened to their concerns, improved the system to achieve the same results in less time, and gained valuable front-line staff buy-in as a result.

- Measure Results: Metrics for measuring improvements are part and parcel with each solution. Every method change has one or more associated KPI with a baseline and target to drive results.

Maximizing the Benefit of Performance Improvement Initiatives in Oil & Gas

Oil and Gas players these days are challenged with several external factors that can potentially corrode their profit margin. Factors such as new environmental policies, demand for higher quality products, growing investments in renewable energy sources, and global geopolitical events - all contribute to today’s market dynamic uncertainty and product price volatility. As a solution, building a more resilient business model with a robust cost structure will be essential for the Oil and Gas operators to secure a more sustainable future.

Identifying the Need for Performance Improvement Initiatives

Among all available opportunities, selecting the correct project and executing it effectively will be critical for today's oil and gas business. Without proper execution, approved projects can result in poor performance and low return on investment. A common root cause of the failure of these projects is the lack of active team collaboration.

A strong team culture that fosters productivity and understanding is essential for the project to be successful. Through our experience, a more engaged project team tends to execute more efficiently, reduce project risk, and capture more benefits through continuous identification of new opportunities.

Building Successful Team Culture in Oil and Gas:

Through our projects with more than a dozen refineries we identified some key enabling factors of a successful team culture:

- Roles and responsibilities of team members are clearly defined (RACI charts)

- Leads for main work areas are employees with strong experience and acknowledged by the team members as an authority

- Strong project management culture and project infrastructure – focus on specific deliverables and timeline

- A shared vision of project purposes and goals

- Culture of cooperation and inclusivity – everyone contributes to solving problems

- Frequent and regular measurement of performance indicators is critical!

With years of expertise in oil and gas performance improvement projects, we had success in helping customers to improve their team performance by defining clear roles and responsibilities, avoiding conflict and drawbacks, and ensuring productivity through constant monitoring of critical key performance indicators. With data collected and information interpreted in a standardized format across customer facilities, we provided structured reviewing processes for these projects and ensured timely corrective actions to safeguard the delivery of the project.

With a people-centric project delivering methodology, we helped our many customers across the globe to successfully achieve excellent performance results where some of these initiatives were previously identified, the project established but eventually ceased to continue due to poor team management. We engaged client organization from top-to-bottom to ensure we always have a comprehensive view and a clear understanding from a different perspective.

Click here to learn more about how to set quality targets and achieve them.

This blog is authored by Anas Dabbakh and Kai Wan. Anas is a Senior Engagement Manager and Kai is an Engagement Manager at Trindent Consulting.

Gasoline Blending - What quality targets should be set to and how to get there?

When conducting quality giveaway optimization projects for our oil and gas customers, we noticed that on average, refineries are giving away twice as much as they practically can. Another observation from these projects was that the value of performance optimization is usually underestimated initially. In contrast, physical (or structural) constraints are commonly perceived as the prime contributors to quality giveaway and capital projects are usually proposed as the solutions for this loss of opportunity.Read more

Marathon Supplier Recognition Award

Trindent Consulting is thrilled to announce that we have been honored with the prestigious 2019 Supplier Recognition Award from Marathon Petroleum Corporation. This esteemed accolade, presented in the category of Innovative Partnership, serves as a testament to our unwavering dedication to excellence and collaboration.

During the award ceremony held in San Antonio TX, Trindent's President, Adrian Travis, and Senior Manager, Anas Dabbakh, proudly accepted this recognition on behalf of the entire firm. Their presence at the event highlighted our commitment to fostering strong partnerships and delivering exceptional results.

This significant achievement further solidifies Trindent's position as a leader in the consulting industry. We are immensely grateful for this recognition from Marathon Petroleum Corporation and remain steadfast in our commitment to driving innovation and success for our clients. Here's to continued collaboration and success!

Interviewing for Success at a Management Consulting Firm for New Graduates

One of the most frequently asked questions we get when we go to recruitment events at the prominent schools for MBAs is: What is Trindent looking for? It is the best question anyone wanting to join a firm can ask. The answer will give the exact information you need to get an idea of what the culture of a firm is about and what kind of qualities and skills are needed to be successful. Likely, the person who you are asking will conjure up images of the most successful people in their organization and give you the list of qualities they believe contributes to these people’s success. At Trindent, we give a very thorough explanation of what we are looking for in candidates in the Careers section of our website:

When called for a telephone screen, why not review such a page and think about the most poignant examples from your experiences that demonstrate you have these qualities? By thinking about the examples in advance of any screening with a company, you can then take your example and think about the most powerful way to talk about it when asked at the interview. Powerful answers are short, structured, and vividly create an image for the interviewer of how you will fit with the organization. As you progress through the stages of interviewing with a firm, continue to ask further probing questions of the staff you speak with that dig deeper into what the company is looking for and repeat the process of crafting your examples to best fit the needs of the organization. It also provides an opportunity for you to reflect on whether the fit is there for you too. If you get excited about how many examples you can think of for each of the qualities a firm showcases as important, chances are you will believe that you are a fit, and this enthusiasm and confidence will resonate at the interview.

It can be tough to think of examples that are really salient for the experienced staff you will meet in the later stages of your interviewing. With limited experience, there can be a significant gap between what you have experienced and convincing a Partner that you have what it takes to be a Consultant. However, some forethought prior to an interview can help to structure your experiences into compelling answers.

We are looking for people who can weather the challenges of constantly travelling (flight cancellations, locations that aren’t the most glamourous, and separation from family, friends and other connections for extended periods of time), which requires tenacity and independence. Convince your interviewer that you are highly independent and self-motivated, and provide examples of how you have successfully persevered with very little stability around you and you will demonstrate how you will manage the expectations of the consulting lifestyle.

Influencing clients is a core element of being in consulting. Take an introspective moment and take stock of what is needed to influence clients. How do you build trust with people? How do you build credibility? Is your level of professionalism (dress, demeanor, and credentials) conducive to being seen as a thought leader and a partner in improving their work environments? Senior members of a firm look for candidates that demonstrate emotional intelligence towards influencing people in a variety of ways. As you prepare to interview with a consulting firm, think about some of the trickier situations you have been in where you have had to influence people or a situation in which you didn’t necessarily have formal authority. Think about the tools you used to manage your frustration and problem solve when immediate solutions were not available. Concisely paint the picture of how you effectively influenced and managed through these situations in the past so that your interviewer will believe you are capable of doing it in the field.

Lastly, don’t think of the fall of each year as the only time of year firms are looking to recruit. Currently, Trindent has a few open opportunities for Consultants who have full professional proficiency of Spanish, Cantonese, Mandarin and Japanese on a professional level. We look forward to hearing from you!

Leveraging Feedback Loops in the Workplace

From the time we are small children, feedback loops are part of our everyday lives even if we are unaware of the fact. They hide behind a plethora of names; report cards, speeding tickets, health checks, standardized tests. No matter what aspect of our lives we find them, they all share the same general premise. They inform us of our current state against a set standard. Feedback loops enable us to track our performance and adjust our approach based on that feedback.