Refinery Maintenance: Planning for Success

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality: During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture: Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

Interested in topics related to “Refinery Maintenance”? Click the buttons below to check out our related industry insights.

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Refineries play a critical role in the processing of crude oil and the production of various petroleum products. Within these complex facilities, the storage and management of liquids, such as crude oil, intermediates, and finished products are of utmost importance. To ensure efficient operations, accurate inventory management, and safe working conditions, refineries rely heavily on tank gauging systems. The following will explore the significance of tank gauging in refineries and how it contributes to the overall success of these facilities.

Different Tank Gauging Methods

While different gauging techniques are used depending on the type of tank and the unique properties of the liquid being stored, tank gauging methods can be divided into two general categories – manual and automatic. An automatic tank gauge (ATG) is an electronic device whose purpose is to continuously monitor levels. ATGs also provide refinery operators with details regarding what is happening inside the tank (e.g., changes in level, level warnings, water level and volume, and temperature). Alternatively, a manual gauge can be carried out using one of 2 techniques: innage (tells you the actual depth of the liquid inside the tank) or outage (measures the part of the tank that is not filled with liquid).

While it can be tempting to solely rely on ATGs for information, recall that all equipment must be calibrated to ensure accuracy. Considering the size of storage tanks, a difference of a quarter inch in level measurement could equal thousands of barrels. Now that we have a better understanding of different methods for tank gauging, let’s explore some of the benefits of using a combined approach for ATG and manual tank gauging at the refinery.

Accurate Inventory Management

Tank gauging provides accurate measurement of liquid levels and volumes in storage tanks. Precise knowledge of inventory levels is essential for production planning and scheduling. Accurate inventory data helps optimize storage capacity and minimize product losses. Compliance with Safety Regulations Refineries operate under strict safety regulations and guidelines. Tank gauging ensures compliance with regulations regarding storage tank safety. Accurate level monitoring helps prevent overfilling and the associated risks. Moreover, by eliminating inventory inaccuracy as a potential source for error, the refinery is better able to reconcile mass balance and more efficiently identify sources of loss (e.g., meter equipment issues, density measurements, etc.).

Leak Detection and Environmental Protection

Tank gauging systems play a crucial role in early leak detection. Continuous monitoring of tank levels helps identify potential leaks promptly. Detecting leaks promptly minimizes environmental impact and prevents product loss.

Operational Efficiency

Tank gauging systems enable real-time monitoring of tank levels and product movement. Operators can track inventory levels, identify bottlenecks, and optimize processes. Accurate data helps streamline operations, reduce downtime, and increase efficiency.

Maintenance and Asset Management

Tank gauging systems aid in predictive maintenance and asset management. Continuous monitoring of tank conditions helps identify maintenance needs. Early detection of equipment malfunctions reduces the risk of costly breakdowns.

Integration with Control Systems

Tank gauging systems can be integrated with refinery control systems. Integration allows for seamless monitoring and control of tank levels and operations. Real-time data integration facilitates decision-making and enhances overall refinery control.

Emergency Response and Contingency Planning

In the event of emergencies, such as fires or leaks, tank gauging data is invaluable. Accurate and up-to-date information aids emergency response teams. Tank gauging systems assist in developing effective contingency plans.

Calibration and Accuracy Verification

Regular calibration and verification of tank gauging systems are essential. Calibration ensures accurate measurement and reliable data. Regular verification confirms that the system remains within acceptable accuracy limits.

Operator Safety and Ease of Operation

Tank gauging systems enhance operator safety and ease of operation. Accurate level measurements reduce the need for manual gauging, minimizing exposure to hazards. Automated systems provide operators with real-time information, enhancing situational awareness.

Continuous Improvement and Optimization

In conclusion, refineries are constantly striving for improvement and optimization. Tank gauging data plays a vital role in identifying opportunities for optimization. Analyzing historical data helps refine processes, reduce waste, and enhance overall performance. Tank gauging is an indispensable component of refinery operations. It ensures accurate inventory management, compliance with safety regulations, early leak detection, operational efficiency, and much more. By investing in reliable tank gauging systems and embracing continuous improvement, refineries can achieve optimal performance, maintain safety standards, and contribute to the sustainable growth of the industry.

This article was written by Francesca D’Urso, an Engagement Manager at Trindent Consulting.

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenance efforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Vital Role of Tank Gauging in Refineries: Ensuring Accuracy and Safety

Refineries play a critical role in the processing of crude oil and the production of various petroleum products. Within these complex facilities, the storage and management of liquids, such as crude oil, intermediates, and finished products are of utmost importance. To ensure efficient operations, accurate inventory management, and safe working conditions, refineries rely heavily on tank gauging systems. The following will explore the significance of tank gauging in refineries and how it contributes to the overall success of these facilities.

Different Tank Gauging Methods

While different gauging techniques are used depending on the type of tank and the unique properties of the liquid being stored, tank gauging methods can be divided into two general categories – manual and automatic. An automatic tank gauge (ATG) is an electronic device whose purpose is to continuously monitor levels. ATGs also provide refinery operators with details regarding what is happening inside the tank (e.g., changes in level, level warnings, water level and volume, and temperature). Alternatively, a manual gauge can be carried out using one of 2 techniques: innage (tells you the actual depth of the liquid inside the tank) or outage (measures the part of the tank that is not filled with liquid).

While it can be tempting to solely rely on ATGs for information, recall that all equipment must be calibrated to ensure accuracy. Considering the size of storage tanks, a difference of a quarter inch in level measurement could equal thousands of barrels. Now that we have a better understanding of different methods for tank gauging, let’s explore some of the benefits of using a combined approach for ATG and manual tank gauging at the refinery.

Accurate Inventory Management

Tank gauging provides accurate measurement of liquid levels and volumes in storage tanks. Precise knowledge of inventory levels is essential for production planning and scheduling. Accurate inventory data helps optimize storage capacity and minimize product losses. Compliance with Safety Regulations Refineries operate under strict safety regulations and guidelines. Tank gauging ensures compliance with regulations regarding storage tank safety. Accurate level monitoring helps prevent overfilling and the associated risks. Moreover, by eliminating inventory inaccuracy as a potential source for error, the refinery is better able to reconcile mass balance and more efficiently identify sources of loss (e.g., meter equipment issues, density measurements, etc.).

Leak Detection and Environmental Protection

Tank gauging systems play a crucial role in early leak detection. Continuous monitoring of tank levels helps identify potential leaks promptly. Detecting leaks promptly minimizes environmental impact and prevents product loss.

Operational Efficiency

Tank gauging systems enable real-time monitoring of tank levels and product movement. Operators can track inventory levels, identify bottlenecks, and optimize processes. Accurate data helps streamline operations, reduce downtime, and increase efficiency.

Maintenance and Asset Management

Tank gauging systems aid in predictive maintenance and asset management. Continuous monitoring of tank conditions helps identify maintenance needs. Early detection of equipment malfunctions reduces the risk of costly breakdowns.

Integration with Control Systems

Tank gauging systems can be integrated with refinery control systems. Integration allows for seamless monitoring and control of tank levels and operations. Real-time data integration facilitates decision-making and enhances overall refinery control.

Emergency Response and Contingency Planning

In the event of emergencies, such as fires or leaks, tank gauging data is invaluable. Accurate and up-to-date information aids emergency response teams. Tank gauging systems assist in developing effective contingency plans.

Calibration and Accuracy Verification

Regular calibration and verification of tank gauging systems are essential. Calibration ensures accurate measurement and reliable data. Regular verification confirms that the system remains within acceptable accuracy limits.

Operator Safety and Ease of Operation

Tank gauging systems enhance operator safety and ease of operation. Accurate level measurements reduce the need for manual gauging, minimizing exposure to hazards. Automated systems provide operators with real-time information, enhancing situational awareness.

Continuous Improvement and Optimization

In conclusion, refineries are constantly striving for improvement and optimization. Tank gauging data plays a vital role in identifying opportunities for optimization. Analyzing historical data helps refine processes, reduce waste, and enhance overall performance. Tank gauging is an indispensable component of refinery operations. It ensures accurate inventory management, compliance with safety regulations, early leak detection, operational efficiency, and much more. By investing in reliable tank gauging systems and embracing continuous improvement, refineries can achieve optimal performance, maintain safety standards, and contribute to the sustainable growth of the industry.

This article was written by Francesca D’Urso, an Engagement Manager at Trindent Consulting.

Interested in topics related to “Refinery Maintenance”? Click the buttons below to check out our related industry insights.

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality: During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture: Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to financial or other key performance indicators. In addition, we make sustainability a key part of each engagement, and train your employees to sustain results.

Refinery Maintenance: The Work Management Process

In any equipment intensive sector, there is almost never a quiet day – and a refinery is no exception. Even the best-planned days can be full of interruptions – failures and other unplanned events that disrupt the schedule and cause system slowdowns or outages.

But a well-curated and properly executed Work Management Process can smooth the impact of these disruptions and enable good Risk Based Decision Making so that refineries can reduce the costs associated with equipment failures, inefficient work execution, process interruptions, overtime, and rushed orders.

Typical Work Management Process

During the first part of the process – Work Need Identification – enhanced training can increase operator understanding of the processes and equipment, while empowering them to better identify failures before they occur. Properly designed and executed Preventative Maintenance for each piece of equipment can enable better identification of failing equipment and increase the equipment’s longevity.

Once a failure is identified, the Operator generates a work notification in the refinery’s Computerized Maintenance Management System (CMMS)or Enterprise Asset Management (EAM) software. Often, these systems are not optimally set-up to enable proper data collection, so it’s important that operators receive proper training in order to ensure that work notifications are of sufficient quality and detail with reduced operator variation.

After the notification is submitted to and approved by a supervisor, a Planner determines which craftspeople and tools are required to fix the failure and how long the work will take to complete. An inaccurate plan can lead to inefficient Work Order Execution as the proper craftspeople may not be involved, the proper tools may not be available, or the schedule may be inaccurate in terms of its duration. Improving the planning process using accurate data can prevent these deficiencies.

Work Order Scheduling is often a challenging area, as there is a limited amount of both human and financial resources, but a long list of work that needs to be completed. These scheduling meetings are typically the embodiment of “the squeaky wheel gets the grease”, with the loudest individuals in the room receiving the most resources. As a result, Preventative Maintenance efforts tend to be neglected, and this myopic view creates a slippery slope of increased equipment failures in the long-term. Creating Standard Operating Procedures and Work Management Risk Matrices can support work prioritization and strike the balance between preventative and reactive work orders. The same logic can be used to prioritize and decrease the Maintenance Backlog. It’s important to note here that the proper criteria should be used in work prioritization to reach desired outcomes; frequently, refineries use incorrect criteria, which reduces the effectiveness of prioritization efforts.

Work Order Close-out is one of the most important steps in the process but is often neglected or improperly completed. A proper Work Order Close-out results in better data collection and more informed decision making. This information can be used in a continuous improvement process that allows Planners to fine-tune Work Order Planning. Additionally, failure code data can be used to identify root causes of failures and support Defect Elimination programs.

Maximizing Benefits through Advanced Process Control (APC) in Gasoline Blending

Advanced process control (APC) plays a crucial role in real-time analysis and recipe control for optimizing gasoline blending operations. However, to harness the full potential of these systems, users must be aware of key considerations. This article will explore three important caveats when implementing APC in gasoline blending: configuring the objective function, ensuring accurate parameters and constraints, and establishing a robust performance review process. By addressing these aspects, refineries can unlock the benefits of precise process control, automation, and financial advantages while adapting to lean operational environments.

Configuring the Objective Function:

To achieve optimal results, configuring the APC system’s objective function is essential. Refineries must customize the solution to align with their specific refinery posture and economic goals. Often, default settings from initial installation are utilized without considering individual circumstances. Refineries should assess and update these settings regularly to maximize performance and value delivery.

Parameters and Constraints:

The accuracy and timeliness of data feeding into the APC system are critical for effective gasoline blending. Refineries must ensure that data sources are up-to-date, reflecting daily operations and incorporating the latest lab data. Careful attention should be given to the calibration and accuracy of the data. Additionally, refining the constraints is vital to strike the right balance. Overly flexible constraints can lead to excessive fluctuations during adjustments, while overly tight constraints may hinder the system’s ability to provide optimized solutions.

Performance Review Process:

Regular performance reviews are essential to ensure that the APC system remains up-to-date and continuously improves. Refineries should establish a robust review process to assess the system’s configuration and identify additional optimization opportunities. By periodically evaluating system performance and exploring new features, refineries can enhance their operational efficiency, identify potential areas for improvement, and capitalize on emerging technologies.

Benefits of a Well-Configured APC System:

A well-configured APC system in gasoline blending brings numerous benefits. It enables precise process control, ensuring the production of optimal-quality gasoline within specifications. The high level of automation reduces manual intervention and empowers process control engineers and operators. In lean operational environments, a well-configured APC system can generate significant financial benefits, potentially amounting to tens of millions of dollars annually.

Conclusion:

Maximizing the benefits of APC in gasoline blending requires careful attention to key considerations. Configuring the objective function to align with refinery goals, ensuring accurate parameters and constraints, and implementing a robust performance review process are crucial steps. By addressing these caveats, refineries can achieve precise process control, automation, and substantial financial advantages in an increasingly lean operational landscape.

Interested in learning more about our services in the downstream sector? Check out our Energy page to explore our expertise and discover how we drive client success.

Interested in topics related to gasoline blending? Click the buttons below to check out our related industry insights.

How to Establish a Good Ethanol Uplift Model?

“How to establish a good ethanol uplift model?” has been a common question when it comes to gasoline blending. With the addition of 10% ethanol to a majority of gasoline products, accurate prediction of the final fuel properties is critical to mitigate margin erosion. With years of experience in blending optimization projects, at Trindent we have developed specific expertise in this area, and here are some insights:

Ethanol Uplift Model Best Practices

Each refinery has its configurations that are developed as a result of the molecules they are making. Therefore, picking the right independent variables to start the development of the model is critical. It starts with understanding the principle of what Octane Number (ON) is, and how this property is related to the chemical molecules inside the gasoline. Typically, a refinery can use as much as 7-8 independent variables, and around 10-15 iterations before finding the perfect model which is not only accurate but also intuitive. The complexity of the model is also important as you want to make it sophisticated enough to provide the accuracy you want, but also simple enough to integrate into the existing system with ease.

Managing Component Distribution

Once a model is developed – the next question would be – how do we optimize it? In addition to adjusting the ON of the neat blend stock (which is often the only approach most refineries take), refineries may take advantage of other property and compositional requirements between to maximize the overall benefit of ON uplift.

Going Beyond ON

While a lot of focus on the ethanol model is about ON, it is imperative to consider other properties that are also affected by ethanol. Therefore, a mature ethanol model system would consider other key properties such as RVP, distillation, and V/L. A good ethanol model system would allow a refinery to achieve method repeatability level giveaway for all their constrained parameters and maximize the benefit from production cost management.

How Does Butane Affect Gasoline Blending?

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity:

Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing:

After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How far in advance does the request need to be placed? Is it feasible to add additional volume? What is the quality of the product and how can it be monitored? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring:

This is one of the most critical factors to consider when managing butane – to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

How to Establish a Good Ethanol Uplift Model?

“How to Establish a Good Ethanol Uplift Model?”

“How to establish a good ethanol uplift model?” has been a common question when it comes to gasoline blending. With the addition of 10% ethanol to a majority of gasoline products, accurate prediction of the final fuel properties is critical to mitigate margin erosion. With years of experience in blending optimization projects, Trindent has developed specific expertise and these are our expert insights.

Ethanol Uplift Model Best Practices

Each refinery has its configurations that are developed as a result of the molecules they are making. Therefore, picking the right independent variables to start the development of the model is critical. It starts with understanding the principle of what Octane Number (ON) is, and how this property is related to the chemical molecules inside the gasoline. Typically, a refinery can use as much as 7-8 independent variables, and around 10-15 iterations before finding the perfect model which is not only accurate but also intuitive. The complexity of the model is also important as you want to make it sophisticated enough to provide the accuracy you want, but also simple enough to integrate into the existing system with ease.

Managing Component Distribution

Once a model is developed – the next question would be – how do we optimize it? In addition to adjusting the ON of the neat blend stock (which is often the only approach most refineries take), refineries may take advantage of other property and compositional requirements between to maximize the overall benefit of ON uplift.

Going Beyond ON

While a lot of focus on the ethanol model is about ON, it is imperative to consider other properties that are also affected by ethanol. Therefore, a mature ethanol model system would consider other key properties such as RVP, distillation, and V/L. A good ethanol model system would allow a refinery to achieve method repeatability level giveaway for all their constrained parameters and maximize the benefit from production cost management.

This article was written by KAI Y. WAN, an Associate Principal at Trindent Consulting. Dr. Wan has collaborated closely with multiple business partners in the energy sector across North America and Asia-Pacific, including some of the world’s largest refineries, and has delivered > $300 MM in financial improvements, with typical project ROIs at 500%–1,500% during the first year after implementation.

Interested in learning more about our services in the downstream sector? Check out our Energy page to explore our expertise and discover how we drive client success.

Interested in topics related to gasoline blending? Click the buttons below to check out our related industry insights.

How Does Butane Affect Gasoline Blending?

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity: Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing: After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How soon in advance does the request need to be placed? How feasible is it to have an additional volume? How is the quality of the product and how to monitor it? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring: This is one of the most critical factors to consider when managing butane – to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

Maximizing Benefits through Advanced Process Control (APC) in Gasoline Blending

Introduction:

Advanced process control (APC) plays a crucial role in real-time analysis and recipe control for optimizing gasoline blending operations. However, to harness the full potential of these systems, users must be aware of key considerations. This article will explore three important caveats when implementing APC in gasoline blending: configuring the objective function, ensuring accurate parameters and constraints, and establishing a robust performance review process. By addressing these aspects, refineries can unlock the benefits of precise process control, automation, and financial advantages while adapting to lean operational environments.

Table of content:

Configuring the Objective Function

Parameters and Constraints

Performance Review Process

Benefits of a Well-Configured APC System

Conclusion

Configuring the Objective Function:

To achieve optimal results, configuring the APC system’s objective function is essential. Refineries must customize the solution to align with their specific refinery posture and economic goals. Often, default settings from initial installation are utilized without considering individual circumstances. Refineries should assess and update these settings regularly to maximize performance and value delivery.

Parameters and Constraints:

The accuracy and timeliness of data feeding into the APC system are critical for effective gasoline blending. Refineries must ensure that data sources are up-to-date, reflecting daily operations and incorporating the latest lab data. Careful attention should be given to the calibration and accuracy of the data. Additionally, refining the constraints is vital to strike the right balance. Overly flexible constraints can lead to excessive fluctuations during adjustments, while overly tight constraints may hinder the system’s ability to provide optimized solutions.

Performance Review Process:

Regular performance reviews are essential to ensure that the APC system remains up-to-date and continuously improves. Refineries should establish a robust review process to assess the system’s configuration and identify additional optimization opportunities. By periodically evaluating system performance and exploring new features, refineries can enhance their operational efficiency, identify potential areas for improvement, and capitalize on emerging technologies.

Benefits of a Well-Configured APC System:

A well-configured APC system in gasoline blending brings numerous benefits. It enables precise process control, ensuring the production of optimal-quality gasoline within specifications. The high level of automation reduces manual intervention and empowers process control engineers and operators. In lean operational environments, a well-configured APC system can generate significant financial benefits, potentially amounting to tens of millions of dollars annually.

Conclusion:

Maximizing the benefits of APC in gasoline blending requires careful attention to key considerations. Configuring the objective function to align with refinery goals, ensuring accurate parameters and constraints, and implementing a robust performance review process are crucial steps. By addressing these caveats, refineries can achieve precise process control, automation, and substantial financial advantages in an increasingly lean operational landscape.

Drive Productivity During Meetings Using These 8 Tips

Drive Productivity During Meetings Using These 8 Tips

Looking to drive productivity during meetings? Follow the 8 tips listed below!

- Chair of the Meeting.

Every meeting should have one individual who is responsible for the management of the meeting itself. A “chair” or “facilitator” of the meeting can be particularly useful if one or more of the participants in the meeting is participating via a conference call. The chair or facilitator can manage the flow of the discussion and reduce participants speaking over one another or cross talking. Another useful technique for conference calls with large numbers of participants is for the chair to introduce the speaker(s) (or the speakers should identify themselves before speaking for the first time) in order to provide identity to the voice, particularly if some of the participants have not previously met or spoken with one another.

- Action Logs.

Assigning action items to individual accountable owners with specific due dates can dramatically increase the effectiveness of a meeting to ensure that the time invested in the meeting attains the maximum benefit. Action logs, or meeting minutes, can be useful for recording these follow up items and responsibilities. In addition, circulating the action logs to other members of the team who were not at the meeting but that may be designated as “Informed“ in the RACI chart, is an effective way of communicating and keeping these individuals informed on the agenda items.

- Close the Laptops.

If participants are going to attend a meeting, they need to be paying attention in order to meaningfully contribute and receive the benefits of attending the meeting. Participants cannot do this if they are focused on responding to emails or reviewing other materials. If necessary, the chair or meeting facilitator should request that all laptops be closed and other electronic communications devices be put away at the start of the meeting. If a participant’s attendance at a meeting is only relevant for certain agenda items, perhaps the agenda could be organized in such a way as to address that participant’s agenda items first (and then that participant can exit the meeting) or last (having that participant join the meeting at a particular time towards the end).

- Time of the Meeting.

Morning meetings earlier in the week (Tuesday or Wednesday) can sometimes be more productive because the participants may be better prepared and engaged (i.e. not trying to catch up on Monday morning emergencies, or focused on getting tasks or reports completed before the weekend). In addition, certain client resources may be working shortened workweeks (3-4 day weeks). With more use of flex hours and long commutes to the office, be careful not to schedule meetings too early in the morning as this may create challenges for the participants.

- Detailed Agendas.

The agenda for the meeting can be a very useful document to executing a successful meeting. In addition to setting out the agenda items to be discussed in the meeting, the format of the agenda can identify who is responsible for each item on the agenda, as well as an estimated period of time for each item on the agenda. The estimated period of time for each agenda item sets expectations for both the person tasked with that agenda item, as well as for the rest of the meeting participants, in trying to manage the time contract for the meeting schedule.

- Food Can Drive Attendance.

If you want / need strong attendance at a meeting, such as an opening meeting on a new client engagement where you need to secure as much buy in for the project as possible, consider scheduling the meeting at lunch time and having lunch catered. Offering lunch requires a little extra planning, particularly if it is at the client site (i.e. special dietary restrictions and preferences; hot vs cold food; sweets vs fruit for dessert) but may result in higher attendance, and may put the participants in a better frame of mind if they are well fed. On the flip side, a poor-quality food can be counterproductive, and may leave a bad taste, so give food the planning it deserves.

- Cautionary Note on Screen Sharing Applications.

Many online meeting technologies now include a screen sharing feature. While these can be very effective in ensuring that all participants are able to identify and understand the specific topic or document that is being discussed, the presenter needs to be very careful that the screen sharing does not inadvertently disclose other confidential information that happens to be visible on the presenter’s desktop. Care should be taken to close any open emails, communication forums and applications before the start of the meeting so that there is no inadvertent disclosure when using these screen sharing applications.

- Face to Face.

While not always possible, there are certain situations where a face-to-face meeting at a client site can be much more effective than a conference call meeting. For example, when attempting to sell a new idea or process change proposal or sell the client on a new piece of business, a face-to-face presentation is often more effective and successful. The presenters can read the client’s reactions in real time, and sometimes more effectively handle in-presentation questions. In addition, the clients generally appreciate their service providers taking the time and effort to travel to the client site, and it gives the consulting team a chance to understand better the client’s work environment and challenges that the client may be facing, as well as identifying opportunities to sell additional services that may be identified by being on site.

At Trindent Consulting, we are a global technical augmentation company with a passion for solving complex problems in the energy, healthcare, and finance sectors. With over 100 client partnerships, our success centers on prioritizing sustainable profit margin improvements and delivering impactful results.

As a medium-sized firm, we cultivate a close-knit environment where every team member knows one another. Our people are fun, and our work is intriguing and diverse. We actively strive to create an inclusive environment where everyone has equal opportunities for growth and success.

Interested in becoming part of our team? Check out our current openings page to find a role that best suits you.

Interested in topics related to “Effective Meetings”? Click the buttons below to check out our related insights.

5 Ps of a Meeting – Ensuring Your Next Meeting is Effective

Consultants excel at solving problems that span across teams, organizations, and industries. By using a variety of methodologies and tools, they can quickly and effectively address issues for their clients—and who doesn’t love a quick and effective solution?

One such issue is ineffective meetings. Fortunately, there are many solutions available, and one of the most effective is ‘the 5Ps of a Meeting.’ This approach is a favorite among consultants for its simplicity, effectiveness, and ability to prevent ineffective meetings from happening in the first place.

By mastering the 5Ps, consultants can transform meetings into productive and purposeful sessions, ensuring every moment spent is valuable and impactful.

So, what are the 5Ps? The 5Ps are Purpose, Participants, Process, Payoff, and Preparation (some suggest it should be 6Ps including Pizza).

Purpose: Every meeting should have a clear purpose, which must be more specific than just a subject line calling for a ‘daily meeting’ (why should the team meet daily?).

Participants: Listing the participants makes the organizer think about who they are inviting and why. The organizer doesn’t have to list the names in the body of the invite, but should nevertheless make a conscious decision about who should be part of the meeting.

Process: How will this meeting be conducted? What is the agenda and the time allocated for each agenda item? This is key, as it prompts the meeting organizer to think about the necessary time for the meeting, helping the team avoid setting meetings in 30-minute chunks just because that is the norm.

Payoff: What does the organizer want to accomplish by the end of the meeting? This should be specific so that the meeting participants can be held accountable.

Preparation: What preparation is needed from the participants? This helps the meeting organizer revisit the payoff and appropriately size the participant list.

Including the 5Ps in every meeting invite is the easiest and most effective way to ensure and prepare for an effective meeting.

Extracting Value from Daily Review Meetings

Daily review meetings are an integral part of the of the active management initiative that organizations hire Trindent Consulting to implement. These meetings have a two-pronged purpose. They give managers a daily opportunity to review KPIs on the team dashboard to gauge progress against targets, and they function as an open forum discussion for staff to contribute ideas, share best practices, and bring up challenges they may be facing.

The first component is straightforward – managers preform the dashboard review while staff listen and absorb. However, in most organizations, the second component of the meeting is a challenging one. When staff are asked to share, the outcome is often not optimal. Staff can be reluctant to speak up if they feel they’re not being heard, or if they believe they can get away with not contributing or being accountable.

Without input from staff, the daily review meetings lose their value. They become an exercise in one-way dashboard review, something that doesn’t require a meeting to be held at all.

Here is where another important tool that Trindent advocates comes into play – the Action Log. When used as part of daily review meetings, it allows managers to instill a sense of engagement and accountability into their staff, thereby maximizing the value of the meetings.

The Action Log Is More Than a Tracker

The action log is more than just “meeting minutes”. It’s a tool that allows managers to record, prioritize, and keep track of the takeaways generated during the meetings in order to keep their team accountable; and it functions as a listening tool to drive engagement.

Unlike meeting minutes, action logs don’t document every discussion point in each meeting, but rather keep an on-going rolling record of the objective to-dos that come up at successive meetings. Each action is assigned an owner and a due date, and the logs are reviewed at the beginning of each meeting to go over what’s been completed since the last session, and at the end of the meeting to confirm new items that have been added.

This level of constant attention to the action items serves to not only ensure that no task slips through the cracks, but it promotes accountability of each staff member to complete their assigned tasks, as anything that’s outstanding will be brought to the attention of the entire team.

The second function of the action log is as a management listening tool to drive team engagement. A common sentiment from employees is that they feel their “voice is not heard” and that “managers don’t listen”. When actions are added to the list and read back to the team at the end of each meeting, it shows the team’s manager has listened to, and understood, everyone’s ideas. By documenting these next step actions, team managers are driving engagement by imparting importance and giving time to the ideas and questions their staff have brought forward.

By using this valuable tool, managers can empower their teams, drive accountability and engagement, and get maximum value from daily review meetings.

5 Ps of a Meeting – Ensuring Your Next Meeting is Effective

5 Ps of a Meeting – Ensuring Your Next Meeting is Effective

Consultants excel at solving problems that span across teams, organizations, and industries. By using a variety of methodologies and tools, they can quickly and effectively address issues for their clients—and who doesn’t love a quick and effective solution?

One such issue is ineffective meetings. Fortunately, there are many solutions available, and one of the most effective is ‘the 5Ps of a Meeting.’ This approach is a favorite among consultants for its simplicity, effectiveness, and ability to prevent ineffective meetings from happening in the first place.

By mastering the 5Ps, consultants can transform meetings into productive and purposeful sessions, ensuring every moment spent is valuable and impactful.

So, what are the 5Ps? The 5Ps are Purpose, Participants, Process, Payoff, and Preparation (some suggest it should be 6Ps including Pizza).

Purpose: Every meeting should have a clear purpose, which must be more specific than just a subject line calling for a ‘daily meeting’ (why should the team meet daily?).

Participants: Listing the participants makes the organizer think about who they are inviting and why. The organizer doesn’t have to list the names in the body of the invite, but should nevertheless make a conscious decision about who should be part of the meeting.

Process: How will this meeting be conducted? What is the agenda and the time allocated for each agenda item? This is key, as it prompts the meeting organizer to think about the necessary time for the meeting, helping the team avoid setting meetings in 30-minute chunks just because that is the norm.

Payoff: What does the organizer want to accomplish by the end of the meeting? This should be specific so that the meeting participants can be held accountable.

Preparation: What preparation is needed from the participants? This helps the meeting organizer revisit the payoff and appropriately size the participant list.

Including the 5Ps in every meeting invite is the easiest and most effective way to ensure and prepare for an effective meeting.

At Trindent Consulting, we are a global technical augmentation company with a passion for solving complex problems in the energy, healthcare, and finance sectors. With over 100 client partnerships, our success centers on prioritizing sustainable profit margin improvements and delivering impactful results.

As a medium-sized firm, we cultivate a close-knit environment where every team member knows one another. Our people are fun, and our work is intriguing and diverse. We actively strive to create an inclusive environment where everyone has equal opportunities for growth and success.

Interested in becoming part of our team? Check out our current openings page to find a role that best suits you.

Interested in topics related to “Effective Meetings”? Click the buttons below to check out our related insights.

Drive Productivity During Meetings Using These 8 Tips

Looking to drive productivity during meetings? Follow the 8 tips listed below!

- Chair of the Meeting.

Every meeting should have one individual who is responsible for the management of the meeting itself. A “chair” or “facilitator” of the meeting can be particularly useful if one or more of the participants in the meeting is participating via a conference call. The chair or facilitator can manage the flow of the discussion and reduce participants speaking over one another or cross talking. Another useful technique for conference calls with large numbers of participants is for the chair to introduce the speaker(s) (or the speakers should identify themselves before speaking for the first time) in order to provide identity to the voice, particularly if some of the participants have not previously met or spoken with one another.

- Action Logs.

Assigning action items to individual accountable owners with specific due dates can dramatically increase the effectiveness of a meeting to ensure that the time invested in the meeting attains the maximum benefit. Action logs, or meeting minutes, can be useful for recording these follow up items and responsibilities. In addition, circulating the action logs to other members of the team who were not at the meeting but that may be designated as “Informed“ in the RACI chart, is an effective way of communicating and keeping these individuals informed on the agenda items.

- Close the Laptops.

If participants are going to attend a meeting, they need to be paying attention in order to meaningfully contribute and receive the benefits of attending the meeting. Participants cannot do this if they are focused on responding to emails or reviewing other materials. If necessary, the chair or meeting facilitator should request that all laptops be closed and other electronic communications devices be put away at the start of the meeting. If a participant’s attendance at a meeting is only relevant for certain agenda items, perhaps the agenda could be organized in such a way as to address that participant’s agenda items first (and then that participant can exit the meeting) or last (having that participant join the meeting at a particular time towards the end).

- Time of the Meeting.

Morning meetings earlier in the week (Tuesday or Wednesday) can sometimes be more productive because the participants may be better prepared and engaged (i.e. not trying to catch up on Monday morning emergencies, or focused on getting tasks or reports completed before the weekend). In addition, certain client resources may be working shortened workweeks (3-4 day weeks). With more use of flex hours and long commutes to the office, be careful not to schedule meetings too early in the morning as this may create challenges for the participants.

- Detailed Agendas.

The agenda for the meeting can be a very useful document to executing a successful meeting. In addition to setting out the agenda items to be discussed in the meeting, the format of the agenda can identify who is responsible for each item on the agenda, as well as an estimated period of time for each item on the agenda. The estimated period of time for each agenda item sets expectations for both the person tasked with that agenda item, as well as for the rest of the meeting participants, in trying to manage the time contract for the meeting schedule.

- Food Can Drive Attendance.

If you want / need strong attendance at a meeting, such as an opening meeting on a new client engagement where you need to secure as much buy in for the project as possible, consider scheduling the meeting at lunch time and having lunch catered. Offering lunch requires a little extra planning, particularly if it is at the client site (i.e. special dietary restrictions and preferences; hot vs cold food; sweets vs fruit for dessert) but may result in higher attendance, and may put the participants in a better frame of mind if they are well fed. On the flip side, a poor-quality food can be counterproductive, and may leave a bad taste, so give food the planning it deserves.

- Cautionary Note on Screen Sharing Applications.

Many online meeting technologies now include a screen sharing feature. While these can be very effective in ensuring that all participants are able to identify and understand the specific topic or document that is being discussed, the presenter needs to be very careful that the screen sharing does not inadvertently disclose other confidential information that happens to be visible on the presenter’s desktop. Care should be taken to close any open emails, communication forums and applications before the start of the meeting so that there is no inadvertent disclosure when using these screen sharing applications.

- Face to Face.

While not always possible, there are certain situations where a face-to-face meeting at a client site can be much more effective than a conference call meeting. For example, when attempting to sell a new idea or process change proposal or sell the client on a new piece of business, a face-to-face presentation is often more effective and successful. The presenters can read the client’s reactions in real time, and sometimes more effectively handle in-presentation questions. In addition, the clients generally appreciate their service providers taking the time and effort to travel to the client site, and it gives the consulting team a chance to understand better the client’s work environment and challenges that the client may be facing, as well as identifying opportunities to sell additional services that may be identified by being on site.

Extracting Value from Daily Review Meetings

Daily review meetings are an integral part of the of the active management initiative that organizations hire Trindent Consulting to implement. These meetings have a two-pronged purpose. They give managers a daily opportunity to review KPIs on the team dashboard to gauge progress against targets, and they function as an open forum discussion for staff to contribute ideas, share best practices, and bring up challenges they may be facing.

The first component is straightforward – managers preform the dashboard review while staff listen and absorb. However, in most organizations, the second component of the meeting is a challenging one. When staff are asked to share, the outcome is often not optimal. Staff can be reluctant to speak up if they feel they’re not being heard, or if they believe they can get away with not contributing or being accountable.

Without input from staff, the daily review meetings lose their value. They become an exercise in one-way dashboard review, something that doesn’t require a meeting to be held at all.

Here is where another important tool that Trindent advocates comes into play – the Action Log. When used as part of daily review meetings, it allows managers to instill a sense of engagement and accountability into their staff, thereby maximizing the value of the meetings.

The Action Log Is More Than a Tracker

The action log is more than just “meeting minutes”. It’s a tool that allows managers to record, prioritize, and keep track of the takeaways generated during the meetings in order to keep their team accountable; and it functions as a listening tool to drive engagement.

Unlike meeting minutes, action logs don’t document every discussion point in each meeting, but rather keep an on-going rolling record of the objective to-dos that come up at successive meetings. Each action is assigned an owner and a due date, and the logs are reviewed at the beginning of each meeting to go over what’s been completed since the last session, and at the end of the meeting to confirm new items that have been added.

This level of constant attention to the action items serves to not only ensure that no task slips through the cracks, but it promotes accountability of each staff member to complete their assigned tasks, as anything that’s outstanding will be brought to the attention of the entire team.

The second function of the action log is as a management listening tool to drive team engagement. A common sentiment from employees is that they feel their “voice is not heard” and that “managers don’t listen”. When actions are added to the list and read back to the team at the end of each meeting, it shows the team’s manager has listened to, and understood, everyone’s ideas. By documenting these next step actions, team managers are driving engagement by imparting importance and giving time to the ideas and questions their staff have brought forward.

By using this valuable tool, managers can empower their teams, drive accountability and engagement, and get maximum value from daily review meetings.

Setting Up for Success: A Beginner's Guide to Consulting

Setting Up for Success: A Beginner’s Guide to Consulting

What exactly do consultants do? This is a question commonly asked of consultants by friends, family, or during coffee chats. The truth is, ‘Consultant’ is a broad term covering a wide range of definitions.

In this article, we’ve condensed the essential skills and benefits common to Trindent Consultants. These are the core ingredients that define the consulting lifestyle, enable us to deliver bottom-line results and represent what you can expect from a career in consulting.

C – Change

In consulting, there are two layers of change that are important to master: (1) the ability to accept change; and (2) the ability to instill change. As a consultant, you need to be able to adapt to changing work conditions and environments. By learning to embrace change and expect the unexpected, you will set yourself up for success. Additionally, as a consultant, you are responsible for influencing the client to trust the solutions you are providing. It is imperative that you can deliver on your promises and establish rapport to implement sustainable changes.

O – Organization

You will work with large amounts of information and data throughout the majority of the engagements you are a part of. You may also work on several concurrent engagements with competing deadlines and priorities. By staying organized, productive, and managing your time, you will be able to complete deliverables with a systematic and efficient approach.

N – Network

You will work with incredibly smart people within your consulting firm as well as on your clients’ teams. This will allow you to build professional relationships with ambitious and talented individuals who you can continue to learn from throughout your career.

S – Solutions Oriented

Successful consultants are solutions-oriented – you enjoy the challenge of solving difficult business problems while uncovering effective and innovative solutions.

U – Urgency

One of Trindent’s core values is Perfection with Urgency. As a consultant, you may have new deliverables pop up with tight turnaround times. It is essential to produce a high-quality deliverable efficiently and effectively to ensure it is client-ready within deadlines.

L – Learning

As a consultant, you are going to work on various projects, with a variety of clients in a wide range of industries so you will certainly not be deprived of opportunities to learn! If you are a curious individual with a love of learning, consulting could be the perfect fit.

T – Travel

One of the most exciting parts of consulting is the opportunity to travel. Trindent’s global client base will allow you to fly frequently, live in hotels, and explore new cities, all while bonding with your engagement team.

I – Initiative

As a consultant, you may be expected to lead your own workstream during an engagement. You should be comfortable stepping up to the challenge and act with little to no supervision.

N – Navigate Ambiguous Situations

At times, you will face challenging and ambiguous business problems. These situations will push you to be comfortable with the unknown and uncover insights from complex problems.

G – Growth

Aligned to the love of learning, working in consulting will expedite your professional growth immensely. Being exposed to a variety of clients, industries, and business practices will allow you to gain unparalleled experience and knowledge within a short timeframe.

Above all, Consultants Make It Happen™. We develop insights, instill change, and deliver sustainable results for our clients. By honing the skills mentioned and demonstrating them during your work or throughout the interview process, you will be setting yourself up for a successful career.

At Trindent Consulting, we are a global technical augmentation company with a passion for solving complex problems in the energy, healthcare, and finance sectors. With over 100 client partnerships, our success centers on prioritizing sustainable profit margin improvements and delivering impactful results.

As a medium-sized firm, we cultivate a close-knit environment where every team member knows one another. Our people are fun, and our work is intriguing and diverse. We actively strive to create an inclusive environment where everyone has equal opportunities for growth and success.

Interested in becoming part of our team? Check out our current openings page to find a role that best suits you.

Interested in topics related to “Building a Career in Consulting”? Click the buttons below to check out our related insights.

How to Successfully Navigate the Case Interview

Interviews are always nerve racking. With a strong desire to put your best foot forward, you can end up putting your foot in your mouth instead. Everyone has done it at one point or another, walking away thinking “wow, that was bad”.

The case interview, a standard step in the hiring process of any consulting firm, has an added element of stress. Not only is your background and character being scrutinized, but so are your problem identification and solving skills. Remaining focused and being clear to let your problem comprehension and concise analysis shine through can be difficult in this situation.

However, as intimidating as a case interview may seem, there are three simple ways to detach from the stress and instead approach the entire process logically to succeed.

Practice

A case interview is no different than any other interview in that you need to present yourself well. However, it does require a much different approach to preparation. When warming up for a fit or a character interview, you polish up on the basics, rehearse responses to standard questions like “why do you want to work here” or “tell me a time you failed and how did you respond”, and generally prepare to speak to content you are well versed in. But in case studies, you don’t know in advance what content you’ll be asked to cover.

So, the first step to preparing for a case interview is to polish your responsive analytical and problem-solving skills by taking advantage of the myriad sample case studies available online. Practice how to separate the stimulus from the question, how to break down the problem, how to identify what information is missing, and how it should be gathered and synthesized.

Do Your Research

Your next step will be to research the company’s terminology.

Study their website and their LinkedIn page, and read any publications you can find in order to learn what their “language” is. A quick perusal of Trindent’s website and LinkedIn page, for example, will show a treasure trove of vocabulary and expressions that make up the standard language we use every day.

Remember to Adapt

During the interview, knowing the company’s nomenclature will help you understand the case, read your interviewer’s queues, structure your responses to fit the company mold, be concise in your answers, and hit the right points rather than explaining around them.

It will also allow you to adapt your style to match that of the interviewer. It may seem like a small thing, but the case will be presented using the company’s language, so pivoting to using their terminology will not only help you understand it better, but will also allow your interviewer to easily follow your thought process as you talk through the solution – all of which will translate into higher scores.

Being well prepared for a case interview takes a lot of time, but it also takes a great deal of stress out of it and sets you up to succeed in the next steps of your consulting career.

Interested in becoming part of our team? Check out our current openings page to find a role that best suits you.

Top Reads to Break into Consulting and Succeed

Unlike careers in medicine, law or priesthood, one doesn’t require seven, eight or ten years of education to break into consulting. However, it might often seem that way. Statistically, more and more top business school grads are gravitating towards a career in Management Consulting, so competition has never been tougher. Listed below, are some books that can greatly assist you, not only in breaking into consulting but also in succeeding once you’re there.

-

The McKinsey Way – Ethan M. Rasiel

Quick Glance: The McKinsey Way gives you a quick glimpse into the life of a McKinsey Consultant. The book discussed in simple terms how to run a meeting, how to sell yourself, your business and your ideas, and how to train yourself to think like a consultant.

Why Read? Ethan’s deep dive into the McKinsey way lessens the learning curve associated with many consultancies.

-

Case Interview Secrets – Victor Cheng

Quick Glance: Considered to be the bible for preparing for case interviews. Whether you are brand new to the process or a seasoned vet, this book is the gold standard in giving you the tools to better structure your thoughts, apply logic throughout a case and present and synthesize ideas effectively and coherently.

Why Read? Case Interview Secrets walks you through each stage in the case interview process and the examples at the back are good primers to the real thing.

-

Smarter, Faster, Better – Charles Duhigg

Quick Glance: In this book, Charles Duhigg uses captivating real-world examples to convey ideas on how to improve yourself, your way of thinking and even your business.

Why Read? A big part of consulting is being able to convey ideas to clients using anecdotes and stories to be more relatable and effective.

-

HBR’s 10 Must Reads: The Essentials

Quick Glance: The Essentials are precisely that – the basic requirements of business knowledge that you need to understand how businesses operate in their respective ecosystems.

Why Read? You are often expected to learn quickly when placed on a new study or engagement. Having a working business knowledge can provide the necessary context to help make sense of things.

Interested in learning more career tips? Follow us on LinkedIn for the latest news!

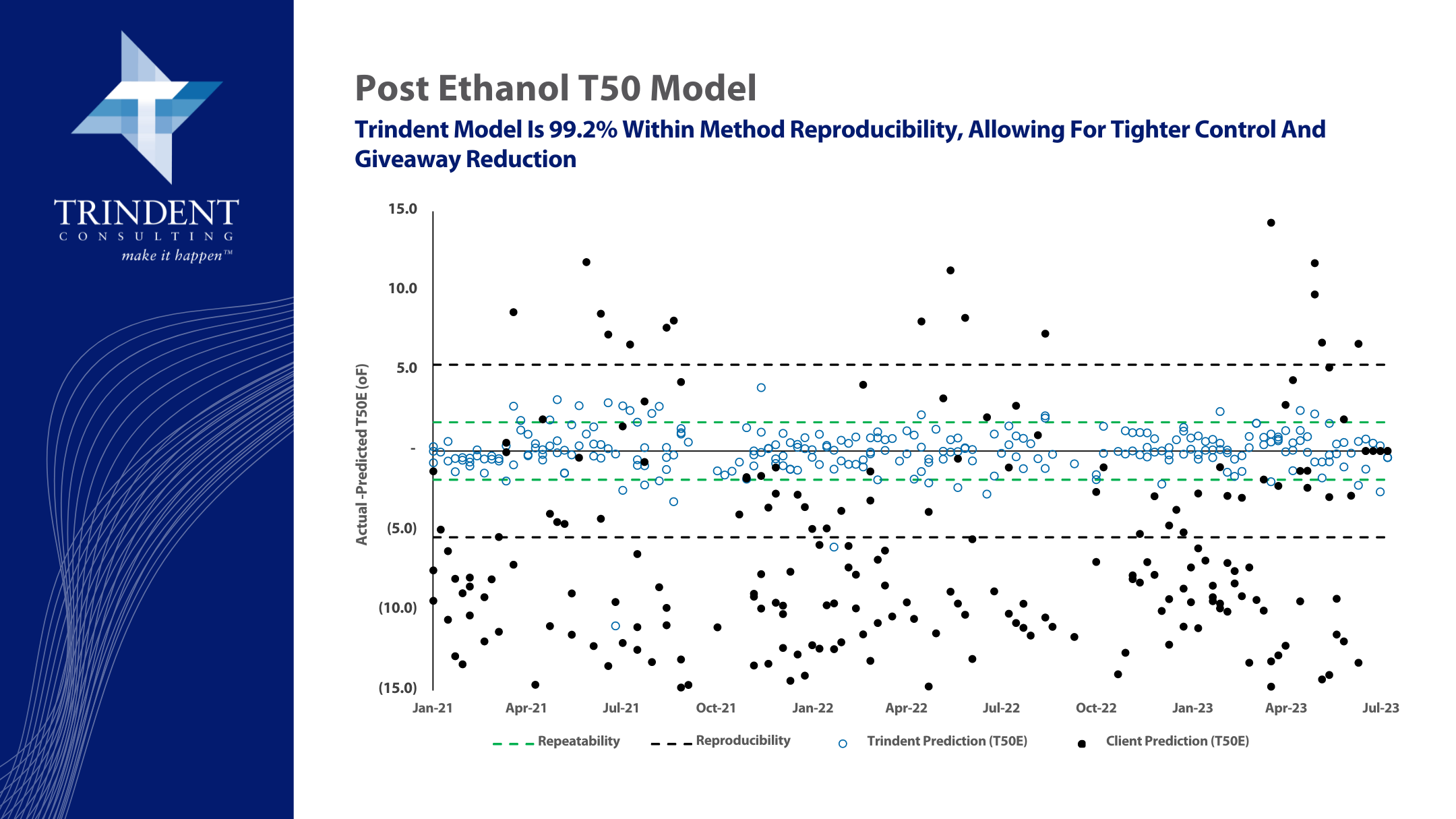

Trindent Develops Accurate Post-Ethanol T-50 Model That Yields $12M in Savings

Trindent is thrilled to share the exciting news of our successful development of an accurate post-ethanol T50 model, marking a significant achievement that has not only resulted in a remarkable reduction in buffers but has also facilitated a 4% increase in butane blending between November and January 2023, translating to impressive financial benefits totaling $12,000,000.

Developing accurate post-ethanol models presents significant challenges for many refineries, particularly when it comes to predicting T50—a key distillation parameter. Ethanol blending exhibits near-azeotrope behavior that severely affects the shape of the E10 distillation curve, making precise modeling complex and demanding.