Maximize the Value of Your Consulting Engagement

Sitting down with your executive team,

you’ve digested the findings found in the Opportunity

Assessment that Trindent Consulting conducted on several key areas of your

organization. Impressed, and ready to

achieve the sustainable financial improvements Trindent has outlined, you and

your team decide to

proceed forward with the Engagement proposal.

Before the work starts, here are the three key things you should know in order to maximize the value of your consultants.

- Your Team Plays a Central Role in Steering the Ship

An implantation engagement is a complex process

and can face a number of challenges that would stymie its true value potential.

While consulting teams are used to

working through whatever obstacles they face, being able to collaborate with

the right client team is necessary to keep the engagement on track and maximize

its value.

One example where good client collaboration

is key is keeping the work within scope.

Consultants frequently receive requests to complete or analyze work

outside the defined scope of the engagement.

There are circumstances where these asks may be appropriate, but often

they are not, and they run the risk of sending the engagement down a proverbial

rabbit

hole.

To the person making the request, the

additional task may seem minimal, something that shouldn’t take long given the

expertise of the consultants, but these requests add up, and if left unchecked

can divert attention away from the true objective of the engagement.

In situations like these, consultants necessarily rely on the expertise of the client team to help navigate the ship in the right direction, saving time and avoiding wasted effort in order to maximize the value of the project.

2. Get Ahead of This Detail

When a project enters the Engagement phase,

it’s most likely not the only ongoing initiative within the organization. Most companies will have several on-going projects

running concurrently. The Financial

Evaluation your company will be doing throughout the life of these projects will

see savings being found, but without a clear delineation as to what initiative

they originated from.

Halting or delaying any engagement schedule

to ascertain the source of benefits is counterintuitive to adding value. It’s easy to get caught up in details, but

project schedules need to stay on track and not lose momentum in order to

maximize the savings your company will realize. Therefore, it’s important for your leadership

team to know when projects go live and what benefits they are projected to find. This way, savings can quickly be attributed

to their respective programs and schedules can stay on target.

With a Trindent engagement, you will be able to refer to our Method Change documentation, which will clearly outline the key activities and calculated savings within the cost-benefit analysis to allow you to easily track the savings our initiatives are finding.

3. Regular Project Updates Lead to Success

There is a long-standing belief that consulting projects conceal the value they create or that the achievements of these projects are untraceable. However, part of Trindent’s process is to hold weekly Engagement Status Report meetings with client management teams to update them on progress against targets, to celebrate the wins, and to discuss setbacks or challenges. Project outcomes are openly examined, and annualized savings are reviewed.

These meetings are your team’s opportunity

to maximize the value of an engagement, and it’s therefore important that they

attend the meetings regularly and stay involved as much as possible. The meetings give your team regular and

recurring visibility to the progress of an engagement and whether it’s tracking

against targets. They give your team the

opportunity to provide guidance in areas of challenge, and a chance to voice

concerns that can be resolved before they become a larger issue that affects

the project. These meetings are key to a

successful project outcome.

Maximum Long-Term Value

Trindent engagements aim for sustainable

changes that last and continue to yield benefits for a long time. But it’s critical to have good collaboration

between clients and consultants to maximize the benefits of process, system,

and behavior changes. Your team has an

important role to play in the success of any engagement.

Refinery Maintenance: Planning for Success

As processors and storage become cheaper and more efficient, more and more companies want to analyze increasing amounts of data and use artificial intelligence to support Risk Based Decision Making; and refineries are no different.

Predictive Maintenance offers refineries an opportunity to determine the current condition of equipment to predict when a failure will occur. This gives refineries a potential to reduce Operating Expenses by performing preventative maintenance only when it is warranted and by reducing the costs associated with Reactive Maintenance. Predictive Maintenance programs are high CAPEX and, unfortunately, most refineries do not have adequate processes and quality data available to make this transition worthwhile. Trindent provides refineries with low to no CAPEX solutions that build the fundamentals required to make the first step towards Predictive Maintenance.

Foundations

for Success

Before a refinery can implement a holistic Predictive Maintenance program, they first need to establish a pilot program. Creating the right foundation allows the refinery to plan for success and implement a program using data-driven decision making to determine where the initiative will have the most impact. Proper foundations also allow for improved refinery operations and a reduction in Operating Expenses in the interim.

- Proper Preventative Maintenance: Preventative maintenance reduces the likelihood of equipment failure by performing routine checks or interventions on the equipment. A proper maintenance program will occur frequently enough to detect failures but not be unnecessarily burdensome to maintenance personnel. As part of this, it’s important to understand correct Preventative Maintenance tasks, durations, and crafts people allow for refinery management to focus predictive maintenance efforts on the equipment that cost the most to maintain. Without proper Preventative Maintenance tasks in place, there will be inadequate follow-up action from predictive maintenance findings.

- Data Quality - During the work management process there are many opportunities to collect the right data; however, refineries often lack the processes and training to collect data that is sufficiently detailed. Improving maintenance programs for instruments and sensors allows the refinery to identify whether the quality of the data is adequate or if the right sensors are even in place. Better data quality allows for management to focus predictive maintenance efforts on specific failures that result in process interruptions. Furthermore, the use of Defect Elimination programs can give the refinery insights into the conditions that cause failure, allowing for a more effective predictive maintenance program.

- Culture – Without building a proactive culture, a predictive maintenance program is destined to be an expensive, but short-lived endeavor. Establishing the right training, tools, dashboards, and communication methodologies allows for results to be sustained. Once the refinery has shifted from a reactive to a proactive culture then the predictive maintenance program can be successful.

At

Trindent, we focus on tangible results and showing improvement through data. This data-driven approach links our results to

financial or other key performance indicators. In addition, we make sustainability a key

part of each engagement, and train your employees to sustain results.

The author of this article - James Greey is a Senior Consultant at Trindent. To learn more about how Trindent can Make it Happen™ in your company, reach out to our team on LinkedIn or through our Contact Us page.

The Challenge Of Identifying Outdated Processes

In any organization,

there is always a natural bias towards performing a task “the way it’s always

been done”.

This line is notorious in

the consulting world and for good reason: Status quo leads to a lack of awareness of inefficiencies,

causing frustration for staff and a loss of profits for the corporation. It can be compared to driving a car with

slightly deflated tires; the driver isn’t aware of the problem, but it’s still

reducing the speed, fuel efficiency, and safety of the vehicle.

Why It’s Hard to Identify

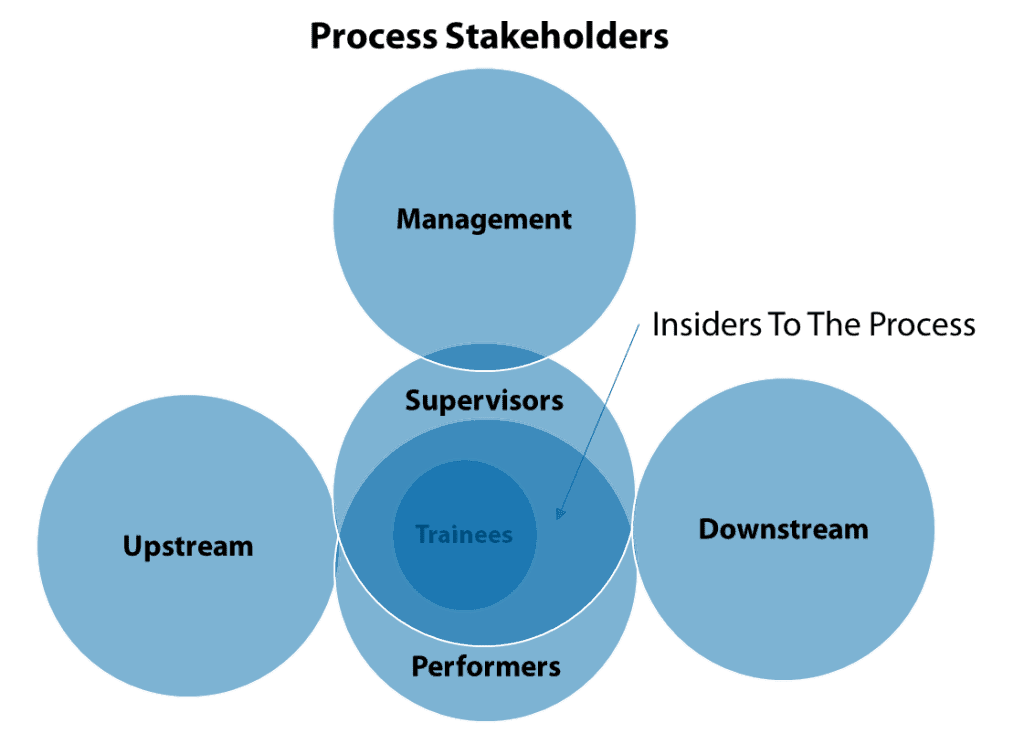

Lack of awareness is the primary cause of process inefficiencies and a major obstacle to operational business process improvement. But if we look at the key stakeholders involved in the lifecycle of a process - suppliers, performers, trainees, supervisors, management, and customers – none of them appear to be the right person to tackle identifying inefficiencies.

For obvious reasons suppliers and customers can be taken out of the conversation – while they are part of the lifecycle, their ability to affect it is minimal. Management usually operates with a degree of removal from any process, so they rarely have sufficient awareness to evaluate the way things are done.

This leaves trainees,

performers, and supervisors as the only stakeholders with enough exposure to become

aware of possible flaws.

Trainees are the entry level participants in a process. Regardless of whether a company has a sophisticated training program or training is done “on the job”, it follows the same pattern: a newcomer is given information they need to process, internalize, and use to hone the skills necessary for their position. Training often overwhelms the trainee with information, and as a result, they rarely have the capacity to question the validity of what they are being taught.

With time, trainees

become performers and this stage of becoming efficient at a process is

the best time to identify its flaws. But

performers often find themselves either under too much pressure from increased

responsibilities, or still too intimidated to speak up. And more often then not, by the time they’ve perfected

the process they’ve been training on, it becomes very difficult to identify

flaws in something they’ve just succeeded at mastering.

By the time a performer

becomes a supervisor, they’ve reached a stage where they’ve internalized

the status quo of the process and it becomes impossible for them to see it with

a critical eye.

Sometimes this cycle

continues for decades.

Two Solutions

Identifying outdated and inefficient processes may be challenging, but it’s not impossible. With a structured approach like lean process improvement principles, or by cultivating a culture of critical thinking, or even by getting more involved in the processes themselves, an organization’s management team can expose and eliminate inefficiencies.

A second approach that will

yield faster and better results is to bring in an outside observer equipped

with robust tools. Performance

consultants are often the best conduit to implementing improvements, as they

can observe and evaluate processes with the impartial eye of a non-stakeholder.

At Trindent Consulting, our approach combines process analysis and improvements with an analysis of systems and behaviours, and working with our clients to implement change.

In the next article of

the Outdated Processes Series, we look at the power of observations.

Telling Your Company's Story With Numbers

When solving problems, management consultants

rely on facts; and their most trusted source for facts is numbers. Numbers hold great power because they cannot

be disputed.

In a consulting engagement, numbers are used at every step. From reviewing a client’s baseline in order to identify business opportunities at the outset, to calculating savings from engagement activities at the end, consultants use numbers to, in essence, tell the story of the engagement. This use of numbers, tracked through various Key Performance Indicators (“KPIs”) and displayed through data exhibits in dashboards and reports, provides consultants with the proof they need to validate their story.

Understand Your Numbers

Likewise for an organization, numbers don’t

tell a story on their own. Instead, they

should be viewed as the building blocks for a story that gets told through KPIs

– the operational indicators used to measure a company’s performance and

financial success. And just like accurate

wording is important to a good story, picking the correct numbers, or metrics,

to be used as KPIs is key to being able to see how an organization is

performing. When communicating through numbers,

there must be an understanding of the message the numbers send.

There is essentially no hard and fast set of metrics that must consistently be selected, and therein lies the challenge of picking the most effective ones. Within any organization, what metrics get selected to be used for KPIs is based on their context and importance within operation, and can frequently change as operational needs evolve. Each company, and each department within that company, will generally have different KPIs unique to their operations, and they must find what combination of KPIs tell the story of their operational performance accurately, without skewing or hiding it's reality.

Display Numbers Effectively

Once KPIs are chosen, the next challenge becomes

displaying them in a way that allows them to communicate their information

concisely. Displaying the KPIs cleanly so

that their message can be conveyed at a glance is key to telling the

operational story.

KPIs should be readable at a glance. When the correct data exhibit is used, and

the KPIs are displayed effectively, they can be scanned quickly to be

understood. However, if there’s a need

to review the KPIs at length to figure out what’s being shown, they are being

presented wrong.

Knowing the appropriate data exhibit to convey a KPI’s information is important, because the data exhibit will dictate how the information will be read. Understanding the KPIs, the information they need to convey, their industry context, the intent of the report they’re being included in, and who the audience is forms the basis for deciding what data exhibit is the best one use.

Seeing the Value in Healthcare

To see the value in being able to effectively tell a company’s story with numbers, let’s look at a healthcare consulting example.

Recently, Trindent was engaged by one of the

world’s leading providers of mobile out-patient telemetry devices to aid in

improving their cost structure and raise service levels, quality standards, and

customer satisfaction. In this

engagement, the indicator to show the desired productivity improvement was the

Gross Referral rate, shown below.

When reporting on the engagement’s success, this data was displayed in terms of project weeks. The improvement chart below shows the improvement trend against baseline numbers. In this case, displaying appropriate information through the correct data exhibit allows for an at-a-glance identification of the baseline and the trajectory of improvement as the project progressed – and the story is told effectively.

Ensuring there is understanding of what

numbers, or KPIs, accurately tell the story of an organization’s current and

future states, and conveying that information with clarity takes time and

planning, but when done correctly, the story that gets told becomes a powerful

tool.

Click here to read more about Trindent’s approach to maximizing the impact of our engagements through KPIs.

The Art and Science of Measuring Productivity

In most organizations, measuring productivity should be a straightforward exercise. But our experience shows that even in companies where productivity should be extremely easy to evaluate – for example, with assembly line production – there is often insufficient attention paid to proper productivity measurement, and proper discipline around undertaking the measurement process is never established or enforced. And in companies that deal with productivity processes that are less straightforward, where production activities have numerous components that are hard to summarize in a limited number of KPIs, these challenges are exponentially exacerbated.

Regardless

of whether measuring productivity in a given organization is simple or

complicated, it’s an extremely high value exercise. The amount of money “left on the table” is

often astounding, and enormous savings are frequently uncovered by Trindent

during our engagements by simply bringing productivity measurement up to an

appropriate level. And yet poor productivity measurement is commonplace.

The phenomenon can rarely be attributed to intentional negligence. Rather, Trindent works with seasoned and savvy executives who lead organizations into this pitfall unconsciously, for reasons like a lack of proper measurement tools, or the lack of political will to change the status quo. Often, an established but inadequate process is left in place for years, its shortcomings becoming less obvious the longer it’s in place. And just as often, organizations are aware of shortfalls in the measurement process, but lack appropriate tools and resources to identify the root cause of the inefficiency and to address them.

In our engagements, Trindent Consulting uses a rigorous three-prong approach to identify the lack of proper productivity measurement, and to establish best practices to fix them:

- Observation: It’s easy to underestimate the power of a fresh perspective, especially one backed by proven methodology and coming from trained process inefficiency assassins. Our consultants dissect and analyze every process, design proper KPIs around them, and identify the proper improvements that need to be implemented to fix them.

- Toolkit: Having in-depth knowledge of a process and how to improve it does not fix the process on its own. The next step in achieving improvement is to build the toolkit to make it happen. Trindent has extensive experience developing and successfully deploying simple but powerful tools to measure productivity. All tools are uniquely developed for each engagement and are never re-used for other clients.

- Experience: Trindent Consulting uses its considerable experience across its three industry verticals to build a base of industry specific process knowledge. While every client is unique, the art and science of identifying the best formula for productivity measurement becomes honed when the exercise is repeated and perfected.

Click here to read more about Trindent’s approach to process improvement in measuring call centre productivity, insurance operations productivity, and healthcare productivity.

Teamwork - A Coveted Skill for Consultants

Teamwork.

It’s a skill most people have on their

resume, but few truly embody.

Although every employer views teamwork as a needed skill, some

professions depend on it more than others.

In consulting particularly, the ability to work effectively and productively with others – whether it’s colleagues or clients – is one of the top consulting skills essential to achieving project success.

Recognizing Challenges Within a Team

In

consulting, we need to work as a team to succeed. This

might sound easy to do, and for some, it is.

However, for a lot of consultants there’s always that one or two people

with whom their personalities and styles just don’t mesh. It could be a co-worker that they don’t get

along with, a client who’s questioning them at every process change, or a boss who

seems to always have it out for them… it seems to be an inescapable part of the

professional landscape.

Being able to recognize these roadblocks to teamwork when they arise and

addressing them effectively takes great skill. When disagreements emerge between colleagues,

for example, they are faced with two choices; either take the easy road out – ignore

the situation and hope it goes away, or jump to confront – which often causes

more harm than good to the team.

It takes real teamwork skill to find the right solution, one that lies

somewhere between ignoring and confronting.

Knowing When

to Listen…And When to Escalate

The first step in working together, especially when facing disagreements and adversity, is knowing how to listen – and knowing the difference between listening to hear and listening to respond.

Listening to hear a team member allows you to understand the

situation from their point of view, which can open your eyes to positions that

you hadn’t considered, and can potentially change your own outlook on the

situation. It also works to keep all members of the team feeling

engaged, valued, and respected. By

allowing open dialogue to then emerge, this alone can often solve a

disagreement before it worsens.

If listening and dialogue didn’t lead to a solution, the next step is escalation. Knowing when – and how – to escalate is extremely important. Recognizing when input from someone outside the team, such as a manager or supervisor, may be needed to settle disagreements is a great example of teamwork skill. While it may seem like appealing to a higher authority in cases of disagreement is antithetical to good collaboration, sometimes the best display of teamwork is the ability to step aside and ask for help for the sake of the team.

Teamwork Contributes to Success

Teamwork sometimes seems like a generic skill everyone puts on their

resume, but to have an in-depth understanding of what that skill entails and to

be able to action it can make a real difference to success in the workplace. The fundamental driver behind a thriving team or

a successful client relationship is strong teamwork.

Refinery Maintenance: Defect Elimination

There

is a famous quote, “insanity is doing the same thing over and over again but

expecting different results.” By this

definition, it is senseless for a refinery to all allow major equipment to fail

the same way multiple times. These types

of failures can lead to expensive production stoppages and result in unplanned

overtime, both of which come at a higher cost than Preventative Maintenance.

At Trindent Consulting we believe in using Risk Based Decision Making to support Defect Elimination – also known as Root Cause Failure Analysis (RCFA).

Defect Elimination is a process to identify the root cause of a failure, determine efficient ways to prevent the failure from reoccurring, and implement those changes. But not all Defect Elimination programs are created equally, and there are key guiding principles that can greatly enhance the outcomes of the program.

- Find the Balance – Once set up, a Defect Elimination program can be a powerful tool; however, it can also be a great burden. It can be tempting to try to use the program to prevent every failure, but this can result in misguided analyses and diminished returns. A proper Defect Elimination program will have thoughtfully crafted criteria for investigation selection and prioritization. We can help you find that balance.

- Accountability – Your employees are hard at work, and Defect Elimination programs can seem like an unwanted distraction and disruption to the normal flow of work. Creating the proper RACI matrices and Standard Operating Procedures (SOP) can streamline the process to become status quo. Without the proper accountability, momentum for the program may vanish. We know how to implement changes in a sustainable manner.

- Common Understanding – The foundation for any strong process is the underlaying system that enables the change to occur in a consistent manner. SOPs are the backbone of a Defect Elimination program. The proper SOP can facilitate the learning process, set clear definitions with terminology, improve the analysis process, and enable the optimal outcome. SOPs create a common understanding that allow for a process to be repeated and reproduced in a consistent and reliable manner. We know how to build strong foundations.

- Right Tools for the Job – Using the right system tools,

methodologies, and frameworks makes the overall program more efficient and

drives results. Using incorrect tools can make the process burdensome,

cumbersome, or altogether ineffective. We

have methodologies, frameworks and system tools that can be quickly tailored to

your needs. Using best practice templates

expedite the execution timeline - allowing for quicker execution and savings.

To learn more about how Trindent can Make it Happen in your company, reach out to our team on LinkedIn or through our Contact Us page.

The author of this article, James Greey is a Senior Consultant at Trindent Consulting

Why Digitization Doesn't Solve Everything

It’s exciting to think of the

opportunities technology has created over the last several decades, and to

imagine how many more are still untapped and underutilized.

One of the most significant changes

technology advancement has had on business has been the digitization of

information and the analytic and communicative power it brought with it. This article looks at why, even with all the

benefits digitization can bring to running organizations, its value can become

diminished if it’s not properly utilized.

Access to Data Does Not

Automatically Provide Business Insight

The business world has historically been at the forefront of capitalizing on digitization because of how much it has enhanced the ability of companies to collect, store, and analyze data. However, gathering information does not mean that it, by itself, it is sufficient, meaningful, or actionable, or that possessing it will automatically lead to sound business decisions. Without having the capability to understand the data you’ve gathered – whether you have the correct data, what it means, how to synthesize it, how to use it to gain insight – it’s an unworkable tool.

A famous example of this is the 2008 collapse of the US economy. Prior to that year’s market crash, Wall Street gathered a glut of information, all pointing to the instability of high-risk sub-prime loans. Lots of people had access to the data, but only Michael Burry, whose story was made famous in the movie The Big Short, knew what to do with it. He knew how to understand what the data meant, acted on it, and made hundreds of millions of dollars while the rest of Wall Street was left in bail-out mode.

The Ability to Reach Customers Does

Not Guarantee the Right Outcome

Another by-product of digitization

is the myriad new ways for businesses to reach their customers. With the proliferation of social networks and

digital media, it became possible to not only reach target audiences in a much

more efficient way, but to also get almost instantaneous feedback about them. Companies gained access to previously unthinkable

levels of detail about their customers’ demographics and preferences.

However, not everyone with access

to that information was capable of using it to their advantage. For every company who knew how to successfully

capitalize on their digital presence to target their customers in just the

right way, there were many more who sunk untold capital into digital marketing

without budging their market share. Why?

Because companies like State Farm Insurance realized that simply gathering

information about clients wasn’t enough; the information needed to be used

correctly for their targeted marketing efforts to successfully drive sales of

their product.

Digitization may now be necessary to compete in today’s marketplace, but without knowing how to utilize this still burgeoning form of communication properly, a business can not guarantee it will help them grow.

Collecting Data Related to Business Processes Does Not Guarantee Efficiency

Similarly, collecting vast amounts

of data about business processes does not automatically give insight into their

efficiency or improvement. Companies can

spend significant capital installing systems to rapidly collect massive amounts

of data, without knowing how to utilize it in a way that justifies the

financial outlay. Management can spend a

disproportionate amount of time generating and looking at irrelevant reports

instead of being handed properly gathered and analyzed data.

Companies still need to apply sound business principles and good analysis of the data in order to use it to help them reach the most correct assumptions. Otherwise, the information, especially in large quantities, may become more of an impediment.

Redefining the Approach to

Digitization

So, while digitization does lead to progress, how do organizations ensure they use it correctly to drive bottom-line improvements? How do they avoid falling into the trap of progress for progress’ sake?

The answer can be found in redefining digitization as a means to an end, rather than a silver bullet for competitive advantage. Organizations need to pivot their approach to begin seeing digitization as a means to create sound management tools because on its own, digitization can’t solve working capital management problems, or revenue growth, or improve key drivers of financial performance. These are processes driven by implementing sound methodology, proper systems, and the right behaviours. Digitization can help achieve these targets of operational excellence, but it can’t get there on its own.

Click here to learn more about Trindent’s approach to creating sustainable and long-term value through its business management consulting services to address core business principles.

Lean Concepts For Knowledge Workers

The core idea of “Lean” is widely recognized even by those

who don’t know the terminology. The

fundamental objective of Lean is to create and maximize value while eliminating

waste. It’s a principle aimed at optimizing

the people, resources, efforts, and energy of an organization with the goal of

creating maximum value for its customer.

Basically, Lean means doing more with less while doing it

better.

The continued success of Lean thinking, principles, and methodology makes it one of the main building blocks of almost every process improvement initiative that consultants tackle.

Adding Value Through the Elimination of Waste

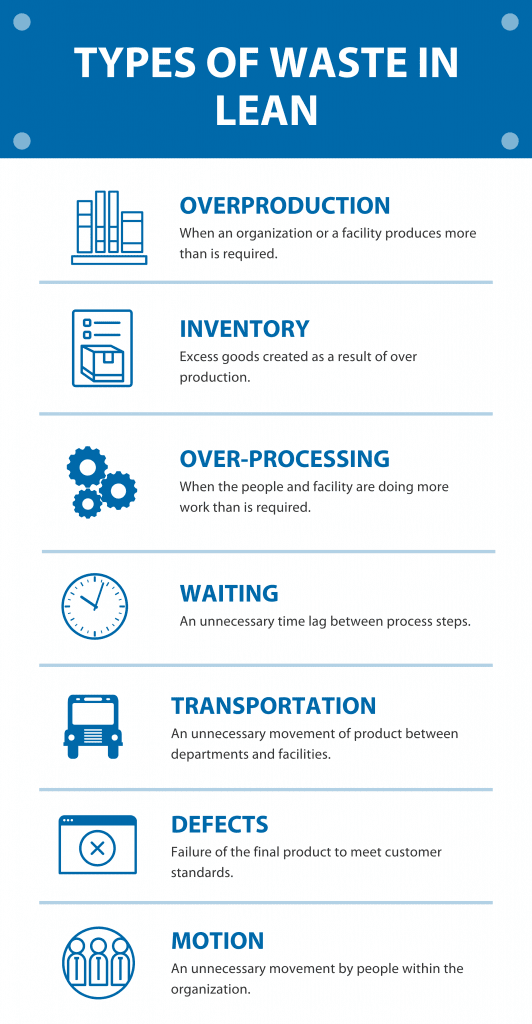

In Lean, there are traditionally 7 types of waste:

Lean practitioners often add an eighth type of waste – unused talent.

When waste is removed, only the necessary steps required to

deliver a product or service to the customer remain in the process.

Using a Lean Lens to Look at Knowledge Worker Efficiency

Although traditionally applied to manufacturing operations, the concept of creating and maximizing value through the elimination of waste applies to any operational processes, including those performed by knowledge workers. A knowledge worker or a “white-collar” worker is defined as someone who uses and handles information and data daily to perform their job.

White-collar jobs tend to be very fluid in structure, constantly evolving, adapting, and innovating to meet current situational needs, so identifying Lean types of waste in knowledge workers can be challenging.

Here are two examples of Lean recommendations Trindent frequently

makes to clients with knowledge workers:

- “Cut and Paste” saves time. Receiving information in an appropriate format plays a huge part in reducing over-processing in a system. Reformatting is a tedious and time-consuming task that can be avoided if the information is transmitted in the correct format in the first place.

- Don’t get consumed by data. Getting fixated on and sidetracked by extraneous details results in trying to juggle too much data and too many KPIs. Focusing on value-added information when setting KPIs will prevent overproduction and accumulation of data inventory. This will keep the process Lean and prevent information clutter from slowing workers down.

Inward Reflection for Consultants

For consultants, Lean should not start and stop with their clients.

As knowledge workers, consultants must practice what they

preach by using Lean

consulting principles themselves. Preforming inward reflections to draw focus on

waste creeping into their work allows them to maximize their own value output.

Consultants need to work in a very lean manner to provide

the maximum possible value to their clients, which in turn will translate to

their clients becoming a lean operation themselves.

The Pyramid Principle: Lessons in Effective Writing

How many times have you read a piece and thought to yourself, what did I just read? I know I do that on the daily and I cannot stop but wonder, do my readers feel that way about my writing? During a discussion about effective communication, a mentor of mine led me to the following book: The Pyramid Principle.

The Pyramid Principle advocates that “ideas in writing

should always form a pyramid under a single thought.” The single thought is the

answer to the question at hand and the supporting arguments are found under.

Then comes evidence for each argument. “Ideas at any level in the pyramid must

always be summaries of the ideas grouped below them.”

Written by Barbara Minto, the Pyramid Principle describes how to effectively structure your written pieces. She argues that by using an answer first methodology, grouping supporting arguments and logically ordering supporting ideas, one can structure their piece of work in a way that is for the human brain to process.

Answer First Methodology

The first rule of effective communication for any consultant is to answer any question ‘answer first’. For many scientists and engineers like myself, this top-down structure is counter-intuitive: it goes against the structure enforced in technical writing such as scientific papers. However, in business, an answer first methodology is the golden standard of effective communication.

An answer first methodology maximizes your time with the audience. From my experience working as a consultant, I learned that executives are busy people who rather know the result instead of the details on how you got to the result. Using an answer first approach, therefore, allows you to provide them with the answer they are looking for in a timely manner.

Moreover, an answer first methodology favors a top-down approach that is naturally easier for our brain to process. Laying out the bigger picture first helps the brain process the remainder of the information.

Grouping supporting arguments

Grouping supporting arguments helps the brain process large

amounts of information at a single time. Take this as an example, which

shopping list would be easier to remember?

- Tomatoes, chew toy for the new puppy, bananas, broom, oranges, dog brush, plates, and toilet paper

- Fruits (tomatoes, bananas, oranges), puppy stuff (chew toy, dog brush) and household items (broom, plates and toilet paper).

Our brain has a natural tendency to group information as it

reads it. Therefore, grouping arguments in writing greatly helps the reader to

categorize information, helping the overall absorption of information. In the

example above, the second shopping list is much easier to remember than the

first because it separates a list of mixed items into three distinct groups.

This principle can and should be applied to writing in a business setting as it will help the writer get his thoughts across effectively.

Logically Ordering Supporting Ideas

Lastly, the organization of evidence is crucial in formulating a compelling argument. You must make sure that evidence grouped together to present a clear inductive or deductive argument.

An inductive argument “will take a set of ideas that are

related simply by virtue of the fact that you can describe them all by the same

plural noun”. An example of an inductive argument is:

- Pomeranians help with alleviating stress

- Samoyeds help with alleviating stress

- Dachshund help with alleviating stress

- Therefore, dogs help with alleviating stress

A deductive argument, on the other hand, presents arguments

in successive steps. An example of this is:

- Businessmen wear ties to work

- Ties are part of a business formal outfit

- Therefore, businessmen dress in business formal

Next time you're about to write something, why don’t you give this pyramid structure a try. I can guarantee that it will lead to more effective communication because it has done so for me!

This blog's author - Meng Zhang is a consultant at Trident Consulting.