In any organization, there is always a natural bias towards performing a task “the way it’s always been done”.

This line is notorious in the consulting world and for good reason: Status quo leads to a lack of awareness of inefficiencies, causing frustration for staff and a loss of profits for the corporation. It can be compared to driving a car with slightly deflated tires; the driver isn’t aware of the problem, but it’s still reducing the speed, fuel efficiency, and safety of the vehicle.

Why It’s Hard to Identify

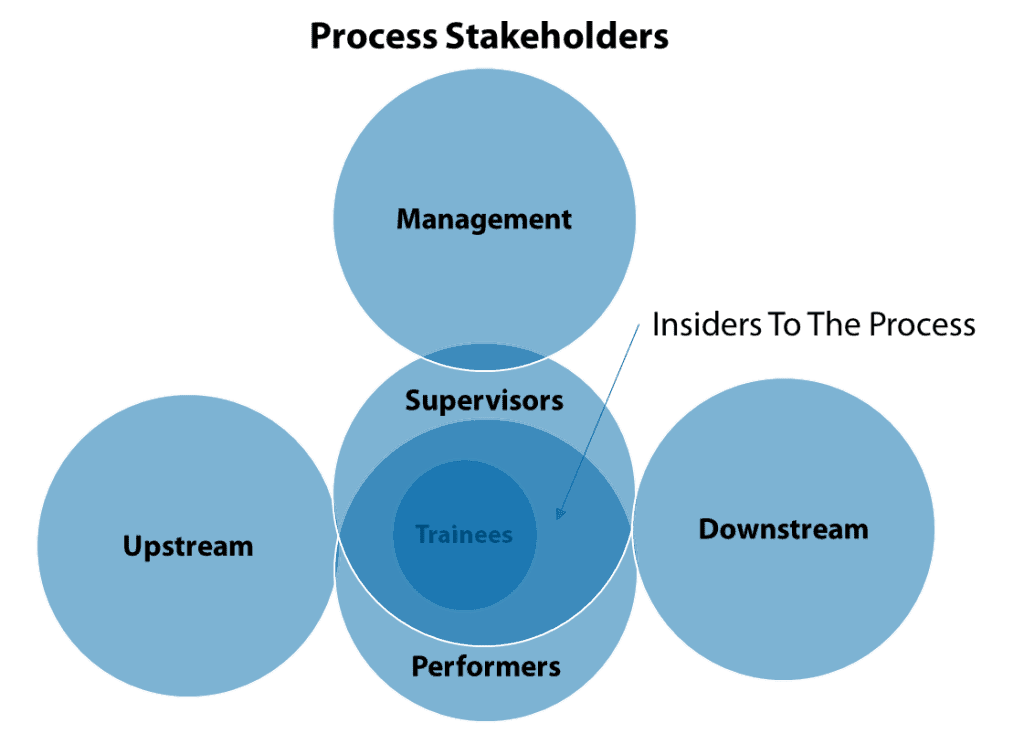

Lack of awareness is the primary cause of process inefficiencies and a major obstacle to operational business process improvement. But if we look at the key stakeholders involved in the lifecycle of a process – suppliers, performers, trainees, supervisors, management, and customers – none of them appear to be the right person to tackle identifying inefficiencies.

For obvious reasons suppliers and customers can be taken out of the conversation – while they are part of the lifecycle, their ability to affect it is minimal. Management usually operates with a degree of removal from any process, so they rarely have sufficient awareness to evaluate the way things are done.

This leaves trainees, performers, and supervisors as the only stakeholders with enough exposure to become aware of possible flaws.

Trainees are the entry level participants in a process. Regardless of whether a company has a sophisticated training program or training is done “on the job”, it follows the same pattern: a newcomer is given information they need to process, internalize, and use to hone the skills necessary for their position. Training often overwhelms the trainee with information, and as a result, they rarely have the capacity to question the validity of what they are being taught.

With time, trainees become performers and this stage of becoming efficient at a process is the best time to identify its flaws. But performers often find themselves either under too much pressure from increased responsibilities, or still too intimidated to speak up. And more often then not, by the time they’ve perfected the process they’ve been training on, it becomes very difficult to identify flaws in something they’ve just succeeded at mastering.

By the time a performer becomes a supervisor, they’ve reached a stage where they’ve internalized the status quo of the process and it becomes impossible for them to see it with a critical eye.

Sometimes this cycle continues for decades.

Two Solutions

Identifying outdated and inefficient processes may be challenging, but it’s not impossible. With a structured approach like lean process improvement principles, or by cultivating a culture of critical thinking, or even by getting more involved in the processes themselves, an organization’s management team can expose and eliminate inefficiencies.

A second approach that will yield faster and better results is to bring in an outside observer equipped with robust tools. Performance consultants are often the best conduit to implementing improvements, as they can observe and evaluate processes with the impartial eye of a non-stakeholder.

At Trindent Consulting, our approach combines process analysis and improvements with an analysis of systems and behaviours, and working with our clients to implement change.

In the next article of the Outdated Processes Series, we look at the power of observations.