Minimizing Refinery Giveaway Through Butane Management

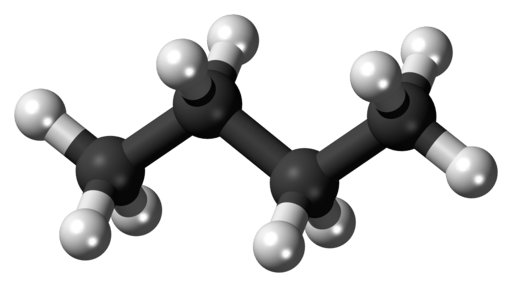

Butane is one of the most important components in gasoline blending and arguably one that could provide the most economic benefit to the bottom line of more and more skinny refinery margins. Butane has a high octane and high RVP which makes it the ideal component to improve the quality of gasoline blends, especially in Winter months. Along with its properties, it has a relatively low cost compared with other components making it the go-to ingredient when blending gasoline. Moreover, it could help companies to reduce the product quality giveaway, i.e. the difference between the specification and the actual product properties. It is estimated that each barrel of butane added to the gasoline blend represents an uplift of $40-50 of the final product.

Factors Influencing Butane Utilization

The management of butane is as important as the product itself considering the relatively large amount of product that is required during blending. To improve how well the butane is utilized, the following factors should be considered:

- Inventory capacity

- Sourcing: Internal production vs. external supply

- Product monitoring

The goal is to have enough butane available when blending in order to optimize the gasoline recipe, minimize giveaway and improve margins.

Inventory capacity: Consider doing a mass balance of butane not only for each blend but for an entire season (mainly Winter) to understand the total amount that will be required. It is recommended to include all the available tanks (accumulation), estimated gasoline production and butane percentage (out) and product sourcing (in). For perspective, butane represents about 10% of the total gasoline volume in wintertime, which is 4-5 times more than in summer.

Sourcing: After the total requirement of butane is determined, an important question has to be asked regarding its source: Is the refinery able to produce the total amount needed? Or does an external supplier need to be involved? If so, how often can you get the product? How soon in advance does the request need to be placed? How feasible is it to have an additional volume? How is the quality of the product and how to monitor it? Planning for the butane sourcing is recommended prior to the season to avoid last-minute pitfalls and secure steady availability through the season.

Product monitoring: This is one of the most critical factors to consider when managing butane - to be able to know the product location, quantity and quality at any given time. The information should be transparent and encompass all the stakeholders including butane storage levels, requirements for blending and other processes, internal movement of product, etc. so that decisions can be made promptly without bottlenecks. Data visualization tools are very important in order to convey information in the most efficient way possible. It is recommended to generate automated data without any additional effort.

Once the analysis is done all stakeholders must come up with a plan to address the weak points, generate solutions, and implement and track them. They can use this analysis to evaluate the outcomes for future seasons or expand to other processes or locations as needed. A combination of technical and managerial expertise is fundamental for excellent butane management in order to understand common problems, physical limitations, product specifications/components properties, and data manipulation. This further helps in engaging with the multi-function teams at different levels, motivating and coaching employees, and providing tools to effectively track results.

At Trindent, we have the expertise to improve the utilization of butane as well as other solutions to reduce giveaway in gasoline blending. Our experience over the last years shows that significant Year-on-Year improvements can be achieved in butane inventory management (up to 100% - 400% additional butane inventory) applying our methodology of changes in systems, processes, and behaviors without any capital investment.

This blog's author - Dom Alvarez, is a Senior Consultant at Trindent Consulting.

Butane Tank image courtesy of Terry Joyce via Wikipedia commons